Introduction

The International Building Code (IBC) and the International Energy Code Council (IECC) continue to implement changes to building codes to reduce energy use. Reducing energy consumption requires tighter buildings with continuous air barriers and higher R-values, thereby reducing the energy that previously allowed components of the building envelope to dry. Vapor impermeable air barriers or roof underlayments can trap moisture, preventing the drying of moisture from within the building envelope, resulting in mold growth and rot. In cold climates, a vapor impermeable air barrier is strategically

installed on the interior (conditioned) side of the building envelope. Should air leakage occur through defects in the the building envelope, warm humid air will make its way through the insulation and condense on the cold exterior or when it reaches dew point.

Energy Recovery Ventilators (ERV) are now required by code to bring fresh air into the building. Malfunction or lack of maintenance can impact the function of the ERV, resulting in stale, humid air build-up within the building. In cold, dry climates, humidifiers are sometimes installed, raising the relative humidity for human comfort and maintenance of components made of hygroscopic materials such as furniture, wood floors, musical instruments, museum pieces, etc. Buildings must be able to dry in both directions, depending on the time of year, through vapor diffusion and heat flow. The performance of an air barrier is not determined by its vapor permeability. Instead, the appropriate vapor permeance level and placement of the air barrier depend on multiple related factors:

- Interior and exterior environments

- Dew point location

- Building pressure: positive or negative

- Moisture sensitivity of adjacent materials

- Location of a secondary air barrier or vapor retarder

The roof enclosure is crucial in protecting the building from the environmental impacts of heat, air, and moisture. The most damaging of these functions is moisture. When moisture enters the roof enclosure, the roof’s durability—and its ability to control wetting and allow drying—become critical to long-term performance. Independent hygrothermal analysis, using WUFI software, validates that the vapor permeance (30 perms) of SlopeShield Plus SA enables drying, while a vapor impermeable ice barrier membrane traps moisture and prevents vapor diffusive drying, allowing moisture to build up, which could lead to long-term roof failures.

Common Roof Issues

- Trapped Moisture = Risk: Roofs that cannot dry are vulnerable to decay, mold, and costly repairs. Impermeable air barriers can cause moisture buildup in the roof assembly.

- Compromised Long-Term Assembly Performance: Roof membranes must prevent bulk water intrusion while also controlling air-transported moisture and allowing appropriate vapor diffusion, when required.

- High-Stakes Liability: Premature roof failures, damage reputations, and budgets.

WUFI Analysis Overview

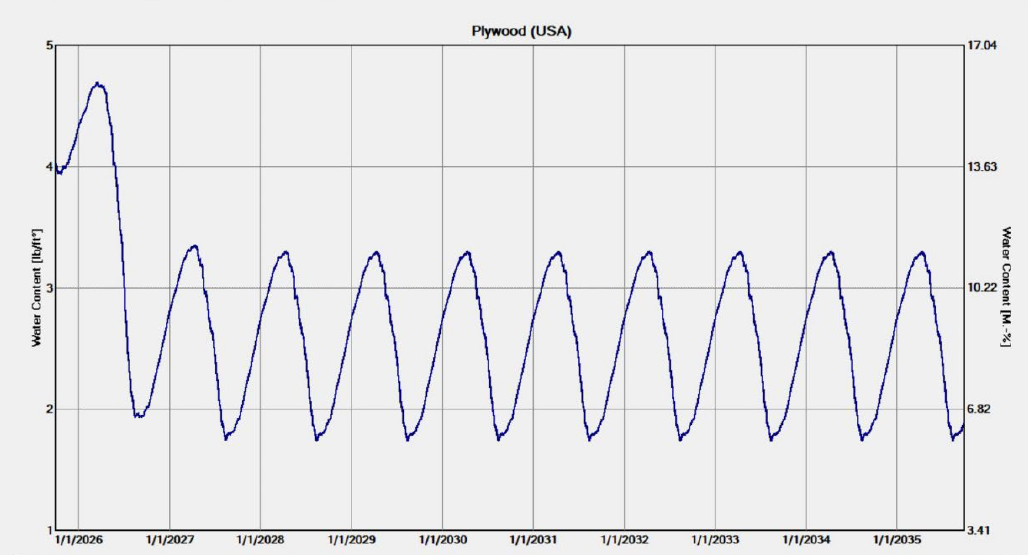

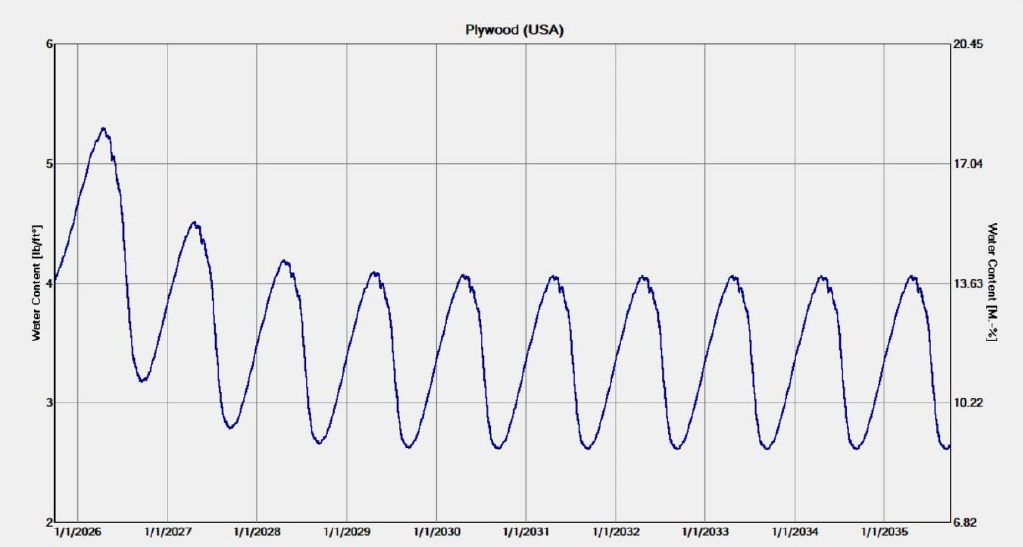

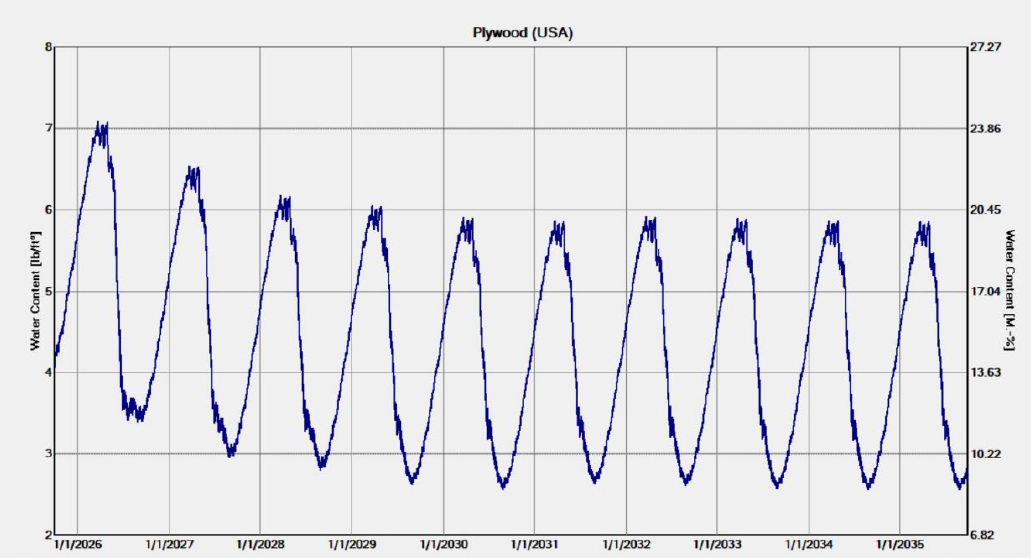

A WUFI analysis was performed using weather data from Boulder, CO, and Billings, MT, to assess the hygrothermal performance (temperature, vapor behavior, and moisture accumulation) of two representative roof systems. The analysis compared assemblies incorporating SlopeShield Plus SA with those using an ice barrier membrane. The scenarios evaluated two building types: a large structure used as a school gymnasium (Scenario 1) and a typical two-bedroom ski lodge (Scenario 2). The moisture content of each roof’s plywood deck was analyzed.

Scenario 1: Gymnasium, Billings, MT

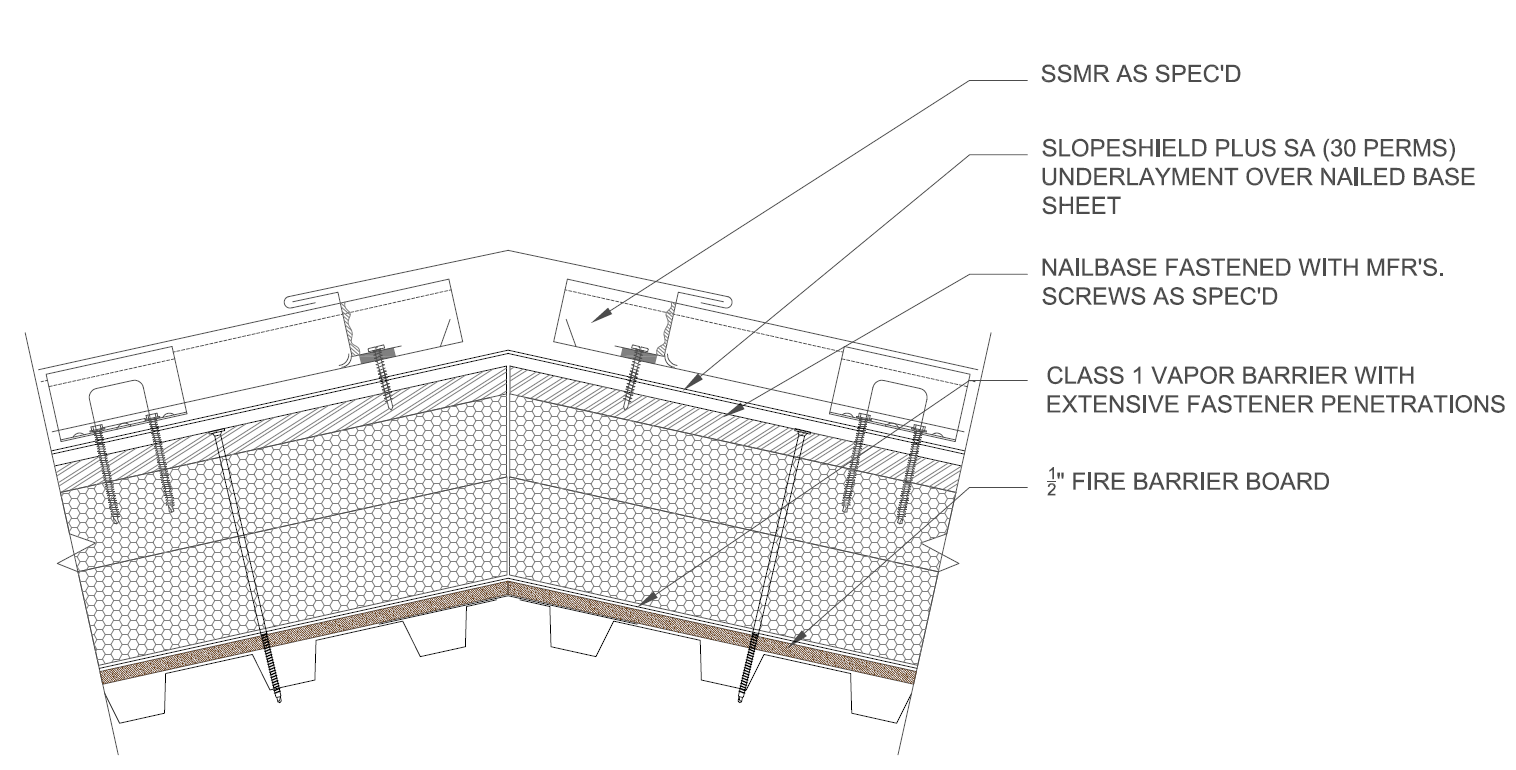

This scenario measured the 10-year hygrothermal performance of a large gymnasium.

|

|

| SlopeShield Plus SA | Ice Barrier Membrane |

|

|

| Moisture levels dropped and stabilized quickly when SlopeShield Plus SA was part of the assembly (3.1–3.4 lb/ft³ within 1 year). | The ice barrier membrane assembly took longer to stabilize, and at a higher moisture level (3.7–4 lb/ft³ within 1 year). |

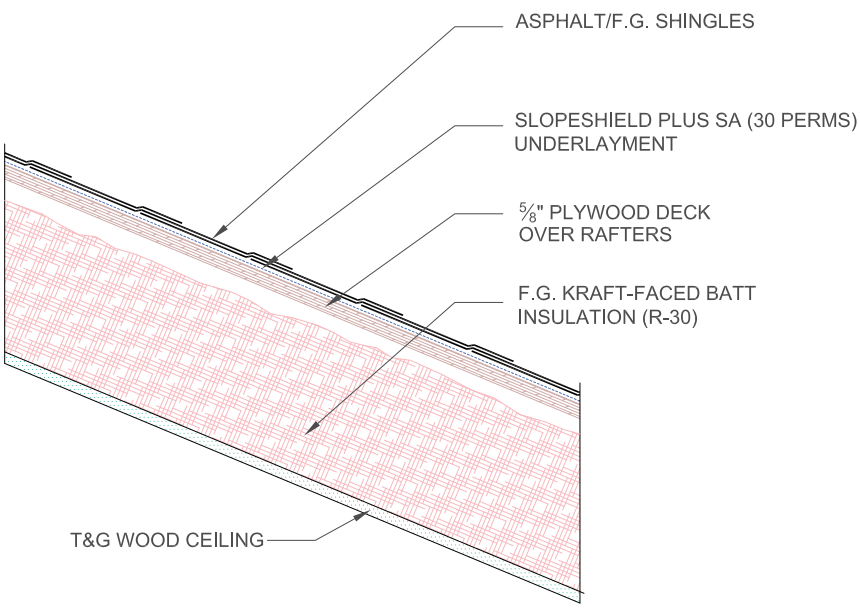

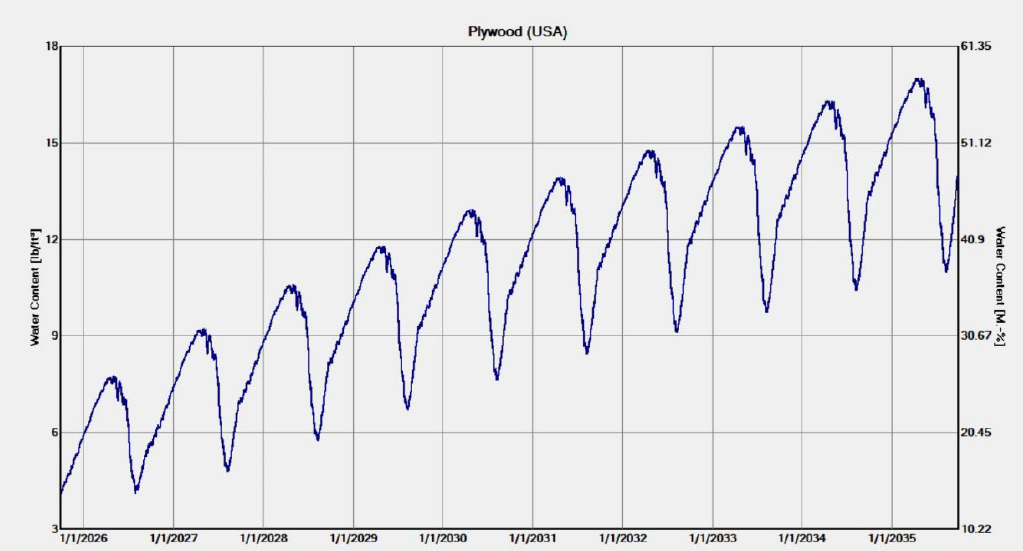

Scenario 2: Ski Lodge, Boulder, CO

|

This scenario measured the hygrothermal performance of a large ski lodge over a 10-year period. This “self-drying” roof scenario does not meet current codes but exists on many older buildings with cathedral ceilings that are not vented. SlopeShield Plus SA promotes drying of moisture that accumulates during the cold winter months. Some code officials in Jurisdictions Having Authority require an ice barrier membrane, per IBC 1507.1.2, over the entire roof, which greatly inhibits the drying effect of the assembly, as shown below to the right. |

|

| SlopeShield Plus SA | Ice Barrier Membrane |

|

|

| SlopeShield Plus SA showed progressive drying, down to safe levels (below 8.25 lb/ft³). | The ice barrier membrane showed ongoing moisture buildup. Reaching 10.5+ lb/ft³ in Boulder and 17+ lb/ft³ in Billings by year 10, with no sign of reversal. |

Long-Term Moisture Protection with SlopeShield Plus SA

- Drying Capability: Assemblies return to safe moisture levels year-after-year using SlopeShield Plus SA, unlike vapor-impermeable membranes that prevent drying.

- Moisture Safety Margin: Moisture content remained below risk thresholds, reducing the risk of long-term damage.

- Healthier Roofs: Prevents high moisture conditions that promote rot and organic growth.

- Durable and Future-Proof: Maintains a high performance roof assembly even in harsh climates in both residential and commercial structures.

- Proven Longevity: Protects assemblies from moisture damage for decades, avoiding hidden vulnerabilities associated with traditional vapor impermeable membranes.

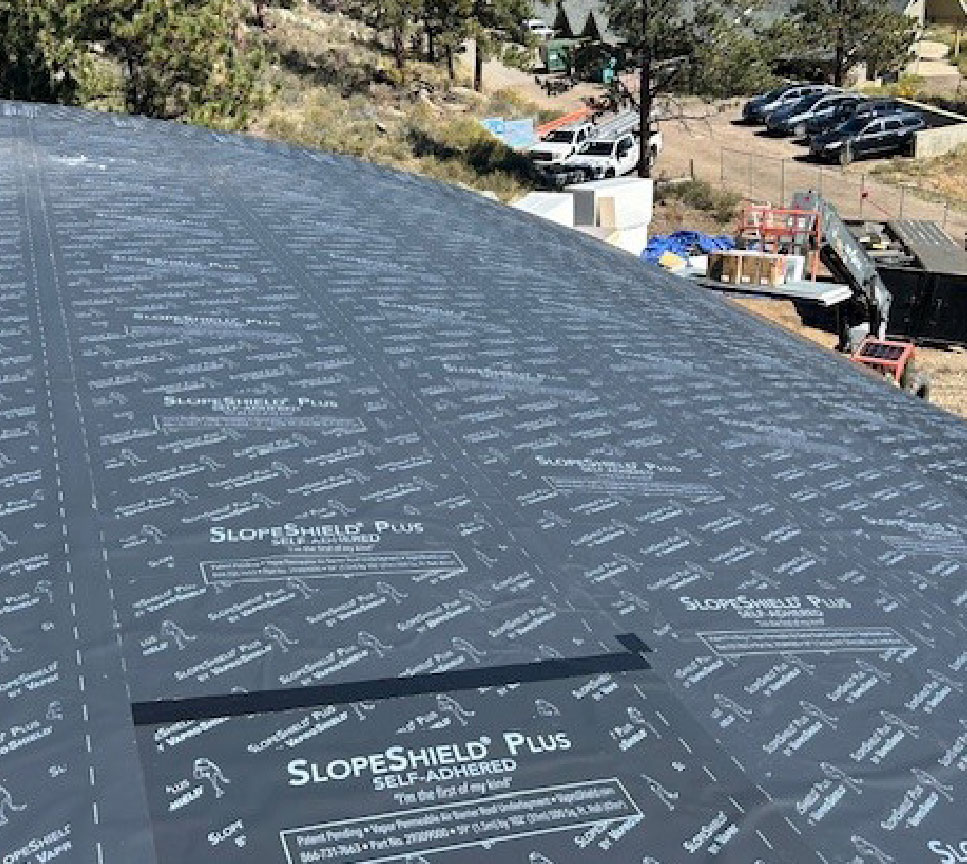

VaproShield Case Studies

| Steamboat Springs Residence | Eagle Rock High School |

|

|

| This Steamboat Springs, CO, residence used SlopeShield Plus SA roof underlayment helping to prevent moisture build-up within the roof materials, resulting in a healthier built environment. | Eagle Rock High School in Estes Park, CO, utilized SlopeShield Plus SA roof underlayment under a barrel shaped metal roof system. Allowing for the roof assembly to dry in both directions. |

Conclusion

WUFI modeling confirms that steep slope roof assemblies incorporating SlopeShield Plus SA consistently maintain safe moisture levels, preserving a healthy moisture safety margin well below critical thresholds. This drying capability supports increased durability, reduces the risk of rot and organic growth, and helps roof assemblies remain resilient—even in challenging climates.