pdf

Printer Friendly

(925 KB)

(PDF)

Printer Friendly Spanish (PDF)

Printer Friendly French (PDF)

Best Practices

|

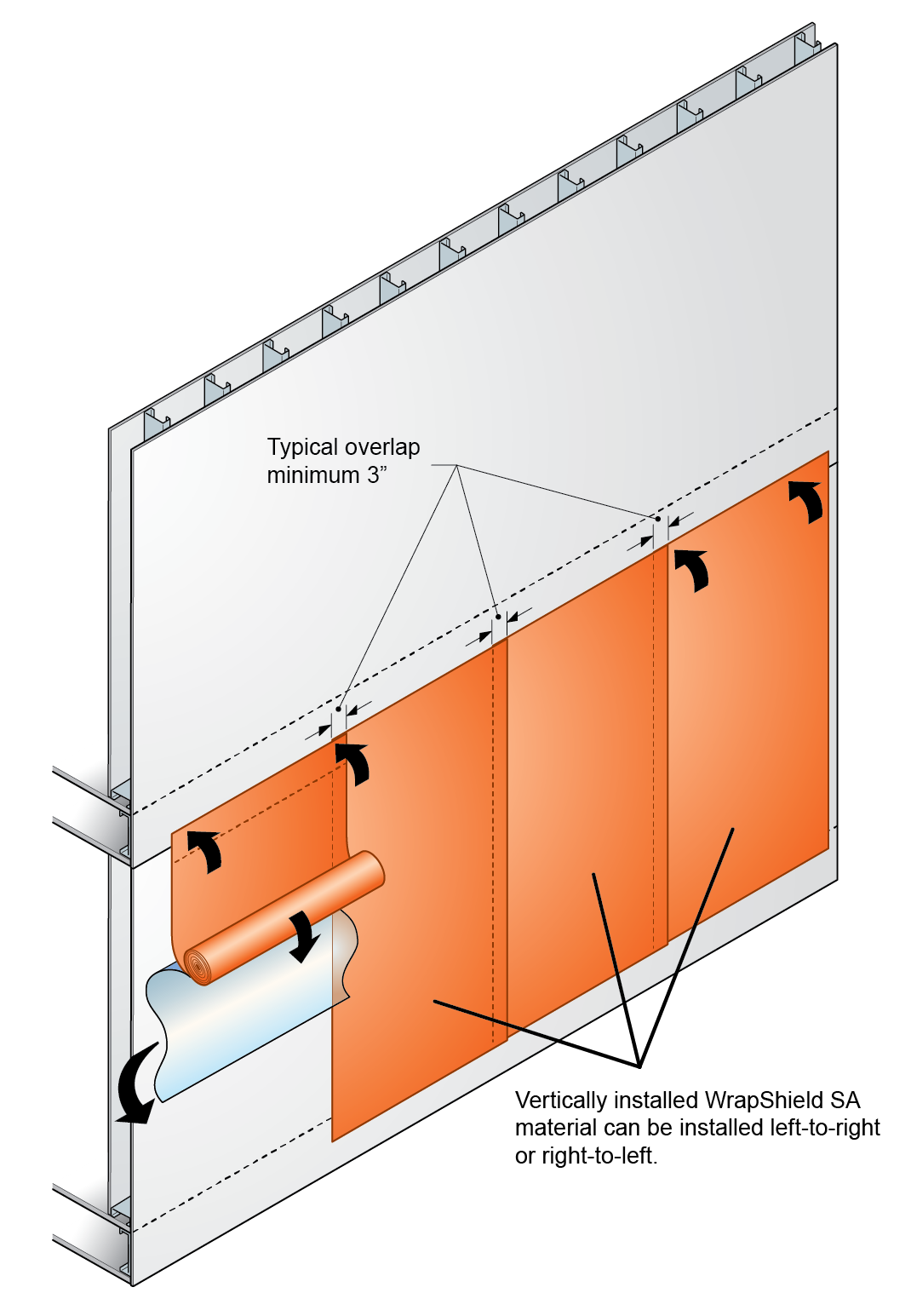

| Figure 1 |

- WrapShield SA Self-Adhered building layout should be planned prior to application to minimize waste, this process will assist locating penetrations that will need to be correctly detailed to ensure a weather and air tight installation.

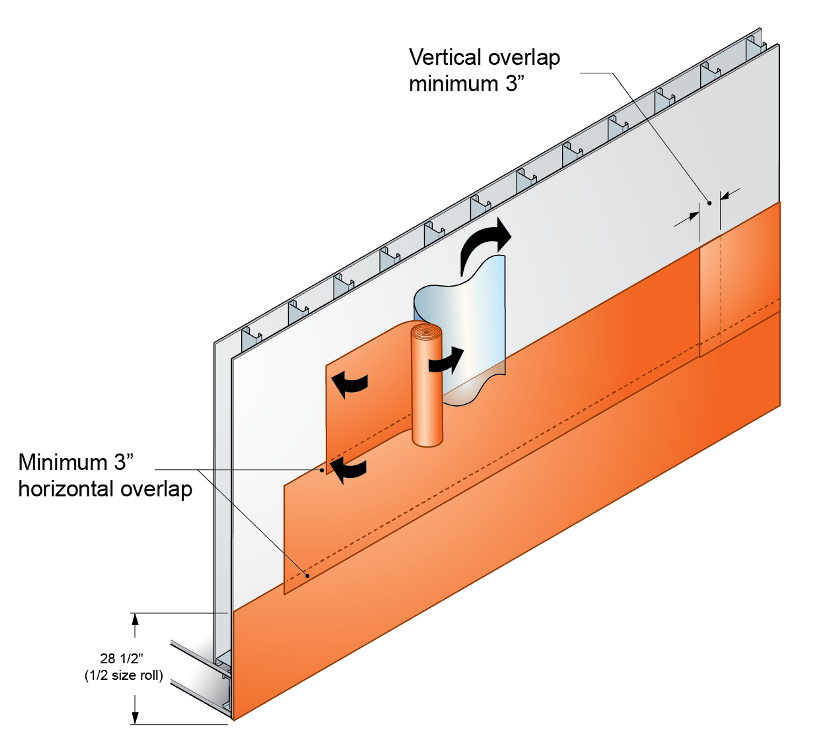

- WrapShield SA Self-Adhered can be installed in a vertical or horizontal direction.

- Always install in a “weatherboard or shingle fashion” with the lower courses lapped under the upper courses.

- All penetrations including windows and doors must be installed in proper sequence to ensure a “weatherboard or shingle fashion” end result.

- All overlaps must be a minimum of 3” (8 cm) on horizontal and vertical seams.

- Inside and outside vertical corners should be minimum 6” (15 cm) of overlap.

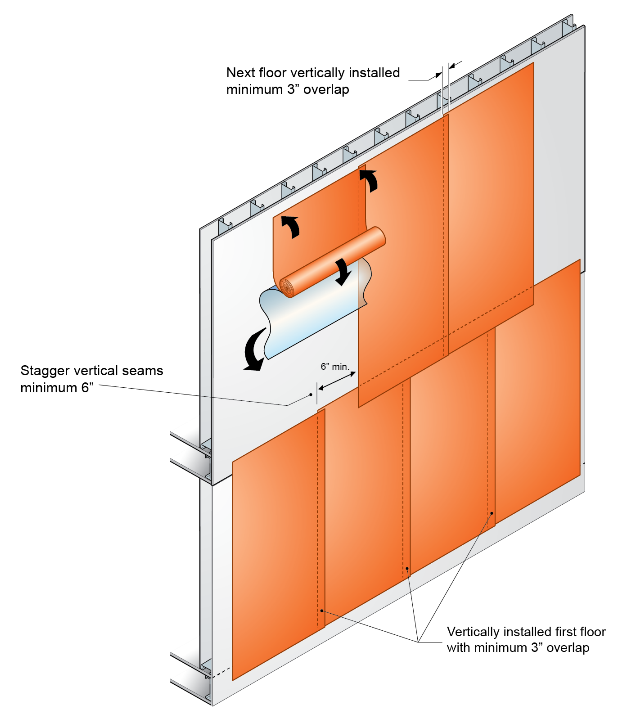

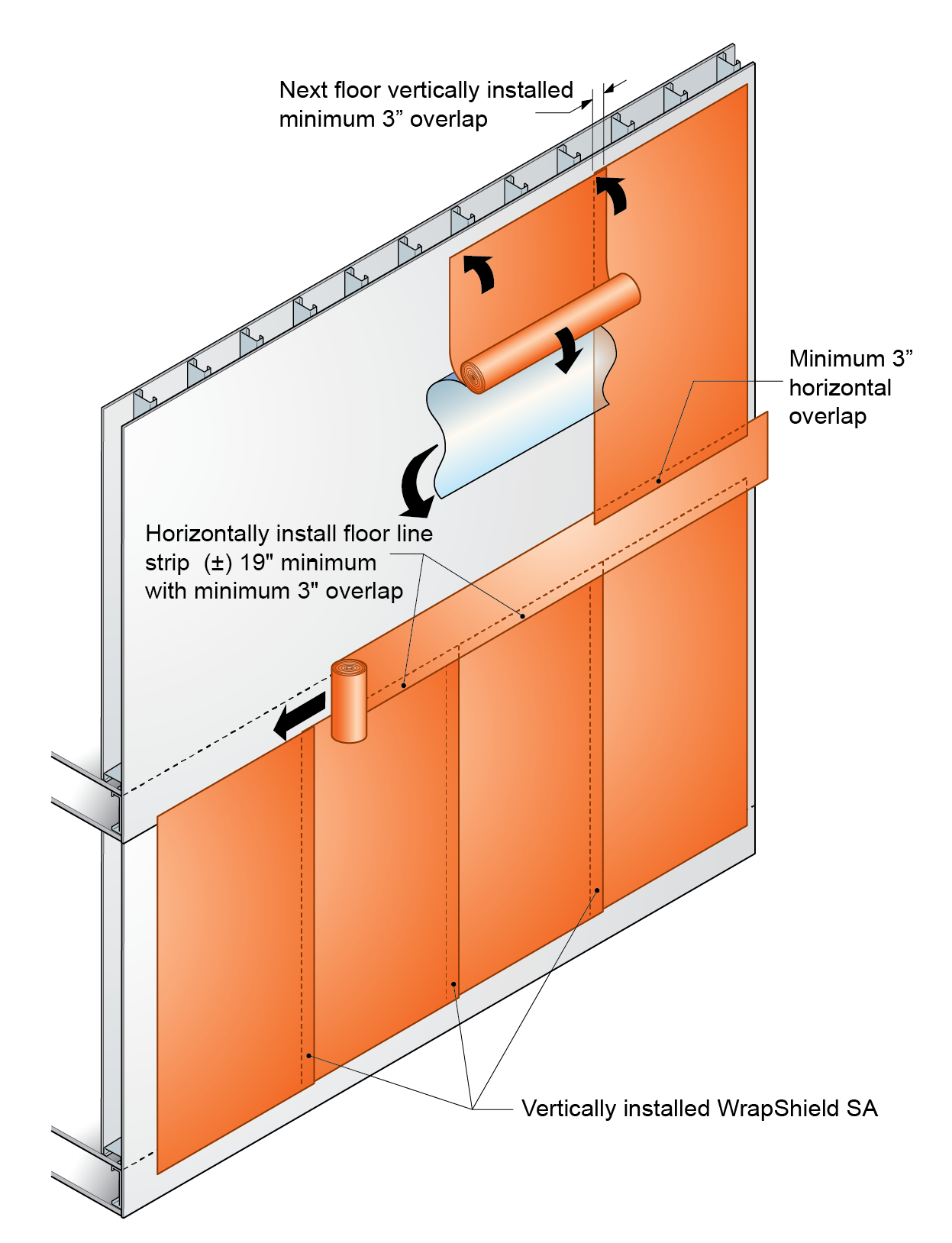

- Vertical seams should be staggered from floor to floor, or separated by a WrapShield SA Self-Adhered horizontally applied strip.

- Roll membrane with two-handed roller to ensure proper adhesion to substrate. (Fig. 1)

- Sustains six (6) months (180) days UV and climate exposure prior to cladding installation.

Substrate Information

- The substrate condition is crucial to the adhesion performance of any adhesive membrane.

- Substrates must be clean and free of any contaminants.

- Substrate surface must be dry to the touch with the ambient temperature above 20°F (-6°C).

- WrapShield SA Self-Adhered can be applied to a wide variety of sheathing substrates:

- GlasRoc

- DensGlass Gold

- Most rigid insulation

- Pre-painted steel

- Precast concrete

- Concrete block

- Plywood

- Aluminum (painted or mill finish)

- Cast-in-place concrete

- Galvanized metal

- Rigid vinyl

- Steel

- Anodized aluminum

- OSB is not an approved substrate for WrapShield SA Self-Adhered. Use PanelShield SA or WrapShield IT Integrated Tape. If you have questions regarding substrates contact VaproShield Technical Team

- WrapShield SA is installed on most substrates without primer. Specific jobsite conditions may require additional surface preparation with primer, contact VaproShield Technical.

Installation Practices

During the installation process, WrapShield SA Self-Adhered must be protected at the leading edge to ensure liquid water does not travel behind the membrane.

Adhesive Curing Time

- Membrane is easily repositioned for up to 30 minutes after initial installation

- Normal curing time is approx. 6 hours.

- Full adhesion will vary depending on job site weather conditions.

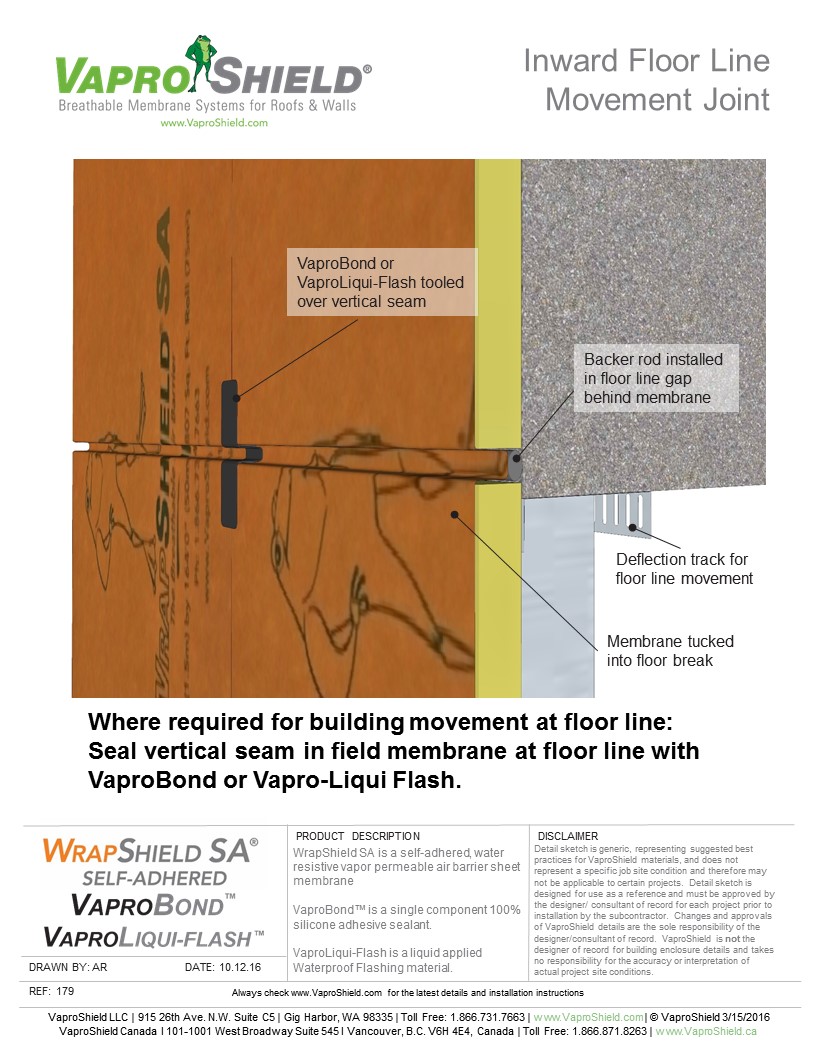

Click here for Floor Line Movement Details

Click here for Floor Line Movement Details

Floor Line Movement

- Buildings are designed to accommodate thermal and seismic movement.

- WrapShield SA Self-Adhered must be installed to allow this movement throughout the life of the structure.

- To accommodate floor-line movement: Limit coverage area to a single floor and shingle subsequent layers over the top leading edge.

WrapShield SA Self-Adhered is Non-Directional

- Install pieces vertically or horizontally.

- Ensure “weatherboard manner” by installing pieces over the top of the pieces below.

- Pieces are easily cut to size.

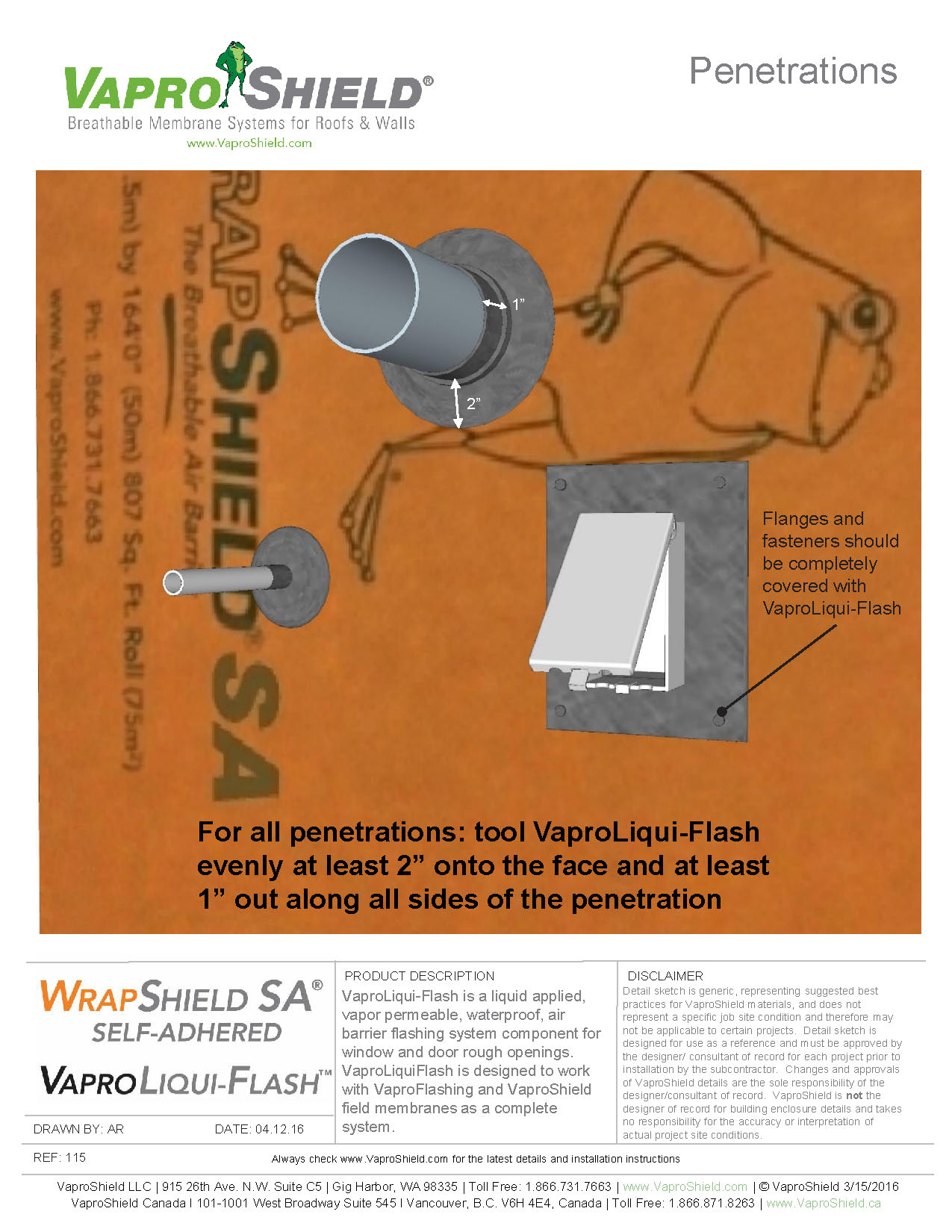

Penetrations

- Window and door penetrations can be detailed pre or post installation of the field membrane.

- Always ensure weatherboard result is achieved.

Click here for Penetrations Details

Click here for Penetrations Details

Original Packaging Functions as Dispenser

- Keep WrapShield SA Self-Adhered in original packaging

- Carefully lift one end of the product out of the box and slide the plastic wrap towards the opposite end.

- Insert roll into end.

- Replace the roll in the box/dispenser and carefully remove the tape in the middle of the roll.

- Keep plastic roll cover to protect partial rolls during installation.

Manageable Lengths

- Pre-cut material into individual manageable lengths by pulling material off the main roll to desired length.

- Cut material square to the factory edges.

- Re-roll material same direction it came off the roll, with the release film outward.

- Cut material to desired length with extended blade razor knife.

Tip: pre-cut material for desired lengths for rough openings. Label as needed on release film with marker.

Single Worker vs. Two Worker Installation

- Using the material at its full width, 59” (1.5 m), vertical installation can be easily accomplished by a single worker.

- Horizontal installation of the full width material is best accomplished by two workers.

- Partial width rolls are easily installed by a single worker.

- View details of installation sequence and view videos on our website for further clarification.

Vertical and Horizontal Installation

Horizontal installation of the WrapShield SA Self-Adhered material is similar to the vertical installation method. The material can be applied either left to right, or right to left.

Best Practice Installation Sequence

- Snap a level chalk line for guidance

- Pre-cut material to desired length

- Roll material with release film facing OUTWARD

- Starting at a corner of the roll, peel back approx. 6” (15 cm) of release film

- Cut the release film with razor knife and tear the cut portion of the release film exposing approx. 6” (15 cm) of glued surface

- Using hand pressure, lightly apply the exposed glue surface to the substrate

- Starting in the middle, use your hands to smooth out air bubbles, releasing the air to each side

- APPLIES ONLY TO VERTICAL INSTALLATION - Allow the rolled up material to drop down the wall, with the remainder of the release film still attached, checking for proper alignment

- Reposition as needed - the material is very forgiving allowing for easy re-alignment

- When aligned, apply heavy hand pressure across the entire adhered section

- Roll up the material with release film facing OUTWARD

- Slowly pull the release film down the wall, allowing the rolled up material to unfurl

- Lightly smooth out air bubbles with wallpaper trowel

- Continue until all the release film has been removed

- Pull back and reposition material (if necessary) as it unfurls

- Apply heavy pressure to the entire substrate to ensure full adhesion

- Roll membrane with two-handed roller to ensure proper adhesion to substrate

- Proceed to next step, ensuring a 3” (8 cm) minimum overlap to the adjoining material, always in a weatherboard manner

Installation Best Practices

- Avoid scoring the membrane at locations where the material overlaps onto the adjacent piece.

- Allow the top layer of material to span across the underlying layer without attempting to force the material into a 90° bend.

- Avoid stretching the material during installation at inside and outside corners.

- A full 6” (15 cm) overlap in either direction is recommended vertically at inside and outside corners.

- If desired adhesion is not attained between membranes due to site conditions, VaproShield recommends applying a bead of VaproBond as an additional solution to pressure rolling.

Storage

- Store vertically

- Keep dry

- Between 40° F and 120° F (4ºC - 49ºC)

THIS IS NOT A SEQUENCE OF INSTALLATION STEPS. EACH IS A SEPARATE SCENARIO

|

|

| Horizontal Installation | Vertical Installation |

|

|

| Multi-Floor Vertical Overlap | Vertical Installation with Horizontal Floor Line |