pdf Printer Friendly (2.81 MB) (PDF)

Overview

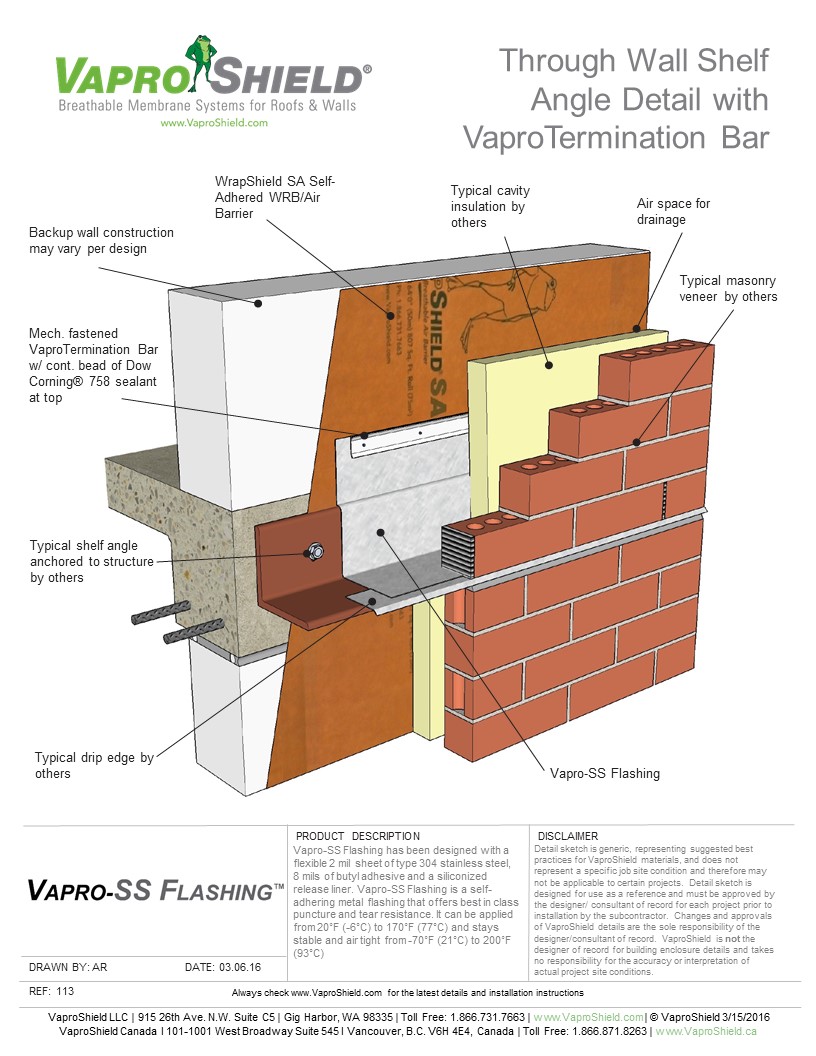

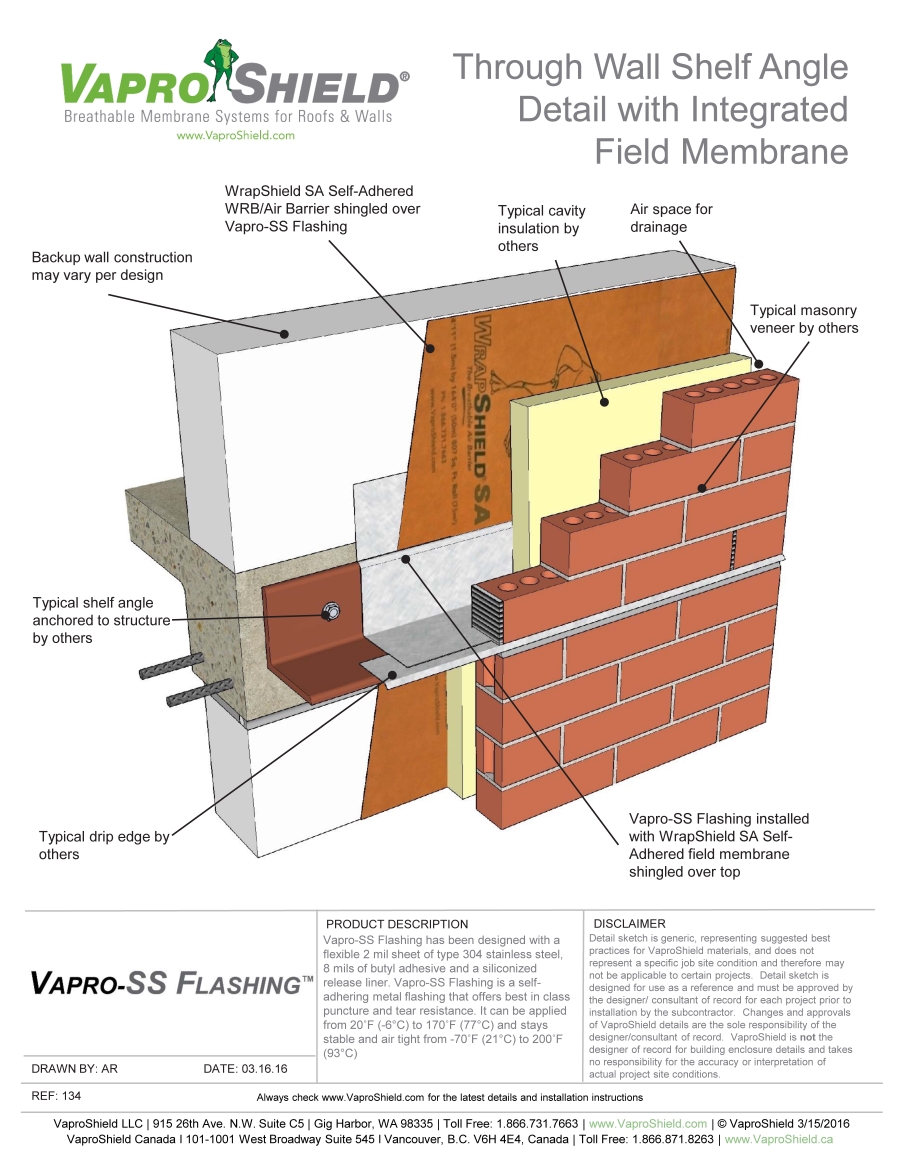

Vapro-SS Flashing has been designed with a flexible 2 mil (0.05 mm) sheet of type 304 stainless steel, 8 mils (0.20 mm) of butyl adhesive and a siliconized release liner. Vapro-SS Flashing is a self-adhering metal flashing that offers best in class puncture and tear resistance.

It is a multi-purpose self-adhered flashing that can perform in various applications, see below examples:

- Through-Wall Flashing for Masonry and Stone structural components

- Transition Membrane (air barriers, WRB, roofing membranes, plaza and below grade waterproofing)

- Curtain Wall Perimeter Flashing

- Window and Door Pan Fabrication

- Jamb Closure Flashing

- Roof to Parapet Transition Flashing

Technical Data

- Flexible self-adhered flashing with a removable release liner that can be installed in temperatures ranging from 20 ˚F (-6 °C) to 170 ˚F (77 °C)

- Stays stable and air tight from -70 ˚F (-57 °C) to 200 ˚F (93 °C)

- Easily adheres to the majority of air barriers, WRB’s, sealants, insulations, below grade waterproofing and roofing membranes, which makes it an excellent transition flashing that is easy to install

- Provides a watertight bond, is mold resistant, fire resistant, and puncture resistant

- Available in 4, 6, 12, or 18 inches x 50 ft. (10, 15, 30 or 45 cm x 15.24 m).

Compatibility

- All VaproShield Materials

- Spray Polyurethane Foam

- Exterior Rigid Insulation

- Exterior Gypsum

- Plywood

- Concrete

- Metals

Storage and Handling

Store material in original packaging. Protect rolls from direct sunlight and inclement weather. Storage conditions:

- 0 ˚F (-18 ˚C) to 100 ˚F (38 ˚C)

- Cover within a few days of installation to protect it from damage from different trades, the environment and falling debris.

- If flashing is left unprotected and it is punctured or torn, contact VaproShield for replacement recommendations, 1-866-731-7663, ext. 5.

- Avoid placing the adhesive with other materials that have high plasticizer contents.

BEST PRACTICE INSTALLATION SEQUENCE

|

|

|

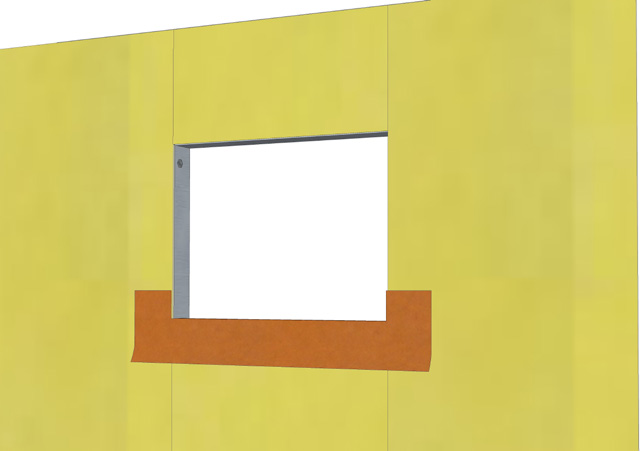

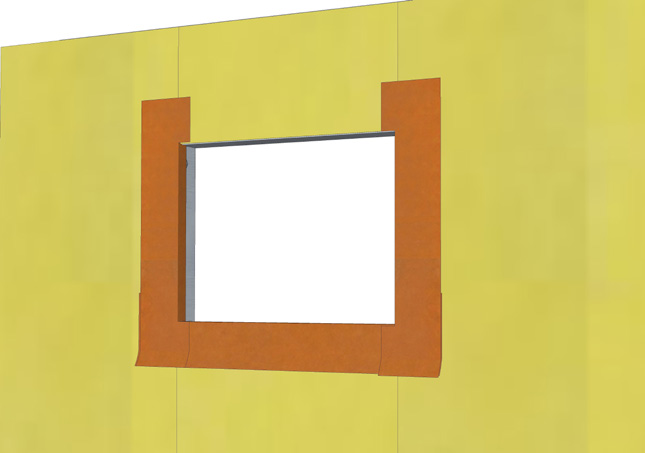

1. Install WrapFlashing SA Self-Adhered into sill with 2.75” folded into Rough Opening (R.O.) 9” left on face, with bottom 6” of release film to remain attached. |

2. Install jamb pieces with 2.75” folded into R.O. 9” to be left on face. |

|

|

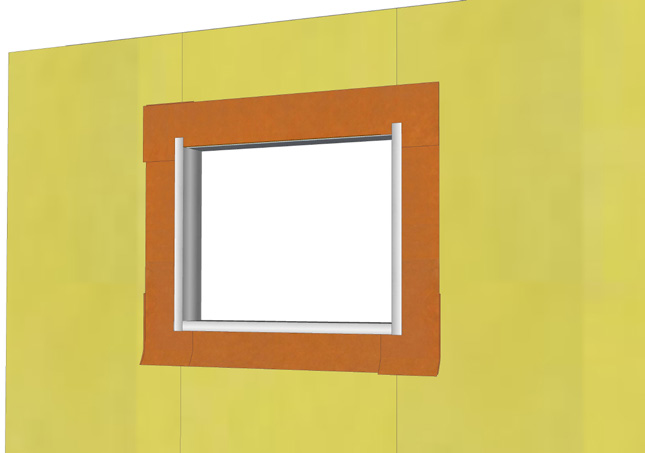

| 3. Install head piece with 2.75” folded into R.O. 9” to be left on face. Roll all WrapFlashing SA (orange) sections with weighted roller to ensure full contact. |

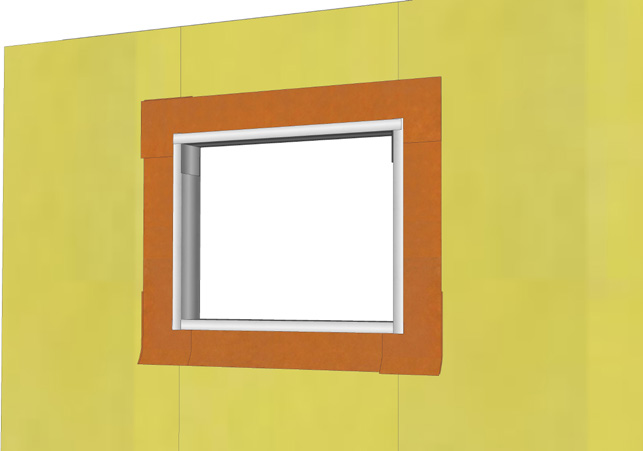

4. Install Vapro-SS Flashing at sill in shingle fashion with 3” up-turned legs at sill and head + 1” on face; jambs are 1” onto the face. See Cut Patterns Detail *To maintain continuity of air barrier system, while allowing for proper drainage at sill, a continuous interior window perimeter sealant joint with backer rod is required. **To determine width dimension of Vapro-SS Flashing required; Measure the depth that the window projects into the rough opening from the exterior face of the wall and add ½”. |

|

|

| 5. Install Vapro-SS Flashing at jambs in shingle fashion with 3” up-turned legs at sill and head + 1” on face; jambs are 1” onto the face. |

6. Install Vapro-SS Flashing on head in shingle fashion with 3” up-turned legs at sill and head + 1” on face; |

|

|

|

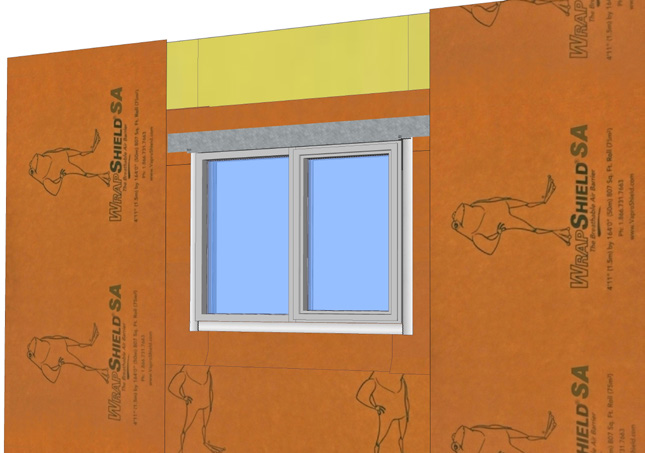

7. Install field membrane underneath 6” flap of sill flashing to create shingle effect, remove release film, adhere to membrane, roll to ensure adhesion at seams (overlaps). |

8. Install field membrane vertically to sheathing, maintaining 3” minimum overlap with R.O. flashing, roll to |

|

|

|

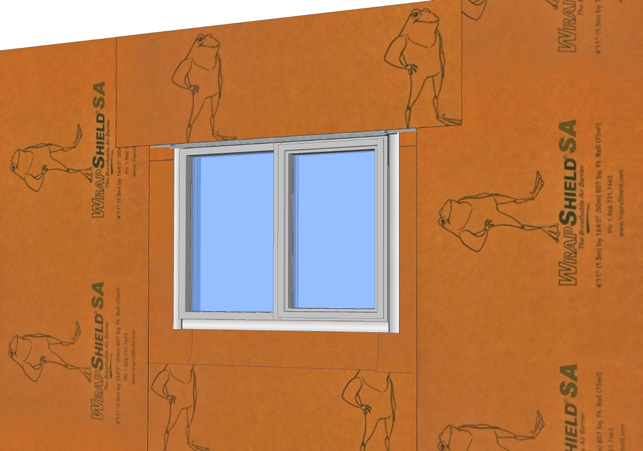

9. Install WrapShield SA field membrane over metal head flashing, maintaining 3” minimum overlap to adjacent field membrane. roll to ensure adhesion at seams (overlaps). |

|

|

*Roll all WrapFlashing SA (orange) sections with weighted roller to ensure full contact. |

|