QUICK OVERVIEW

- UV stable, black or white silicone sealant and all-weather flashing material

- Binds layers of VaproShield membranes and other typical construction materials

- Creates watertight and airtight details

- Applies in 20°F (-6.7° C) and rising

- No primers, easy to gun and apply

Benefits

- Fuctions as a sealant and an all-weather silicone liquid flashing material

- Bonds to most common building materials without priming to produce a durable, structural, air and moisture tight seal

- Remains flexible under extreme temperatures

- Excellent weatherability, UV stable for extended exposure

Compatibility

- Concrete

- Masonry

- Natural stone

- Structural sheathing

- Painted Metals

- Glass

- PVC

- FRP

- EPDM

- Dry wood

- Architectural Metal Panels

- Most building materials, urethane, and acrylic sealants and coatings

Testing

| PHYSICAL PROPERTIES | ||

| PROPERTY | RESULT | |

| Color | Black or White | |

| Composition | Modified Silicone | |

| Minimum Application Temperature | 20°F (-6.7°C) and rising | |

| Service Temperature | minus 60°F (-51°C) - 300°F (149°C) | |

| UV Exposure | Indefinite | |

| Sausage Size | 20 oz. (0.59 L) | |

| VOC Content | 69 g/L | |

| Application as Sealant | 1/4” (6 mm) bead | |

| Application as Flashing | Apply at 30-50 wet mil (0.76 - 1.27mm) | |

| Curing and Drying | At 77°F (25°C) and 50% relative humidity, product is tack-free 25-35 minutes. Higher temperature and/or humidity will shorten this time. |

|

| Warranty | 20 year material | |

| TESTING DATA | ||

| PROPERTY | STANDARD | RESULT |

| Tensile Strength | ASTM D412 Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension | 1.13 MPa (165 psi) |

| Elongation at Break | ASTM D412 Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension | 1500% |

| Modulus, 100% Elongation | ASTM D412 Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension | 0.23 Mpa (33 psi) |

| Water Vapor Transmission Water Method 24.4°C (76.0°F) 50 %RH |

ASTM E96 Standard Test Methods for Water Vapor Transmission of Materials | 6.5 Perm (grains/hr•ft2•inchHg) at 0.36 mm (14 mil) 372 ng/Pa•s•m2 at 0.36 mm (14 mil) |

| Water Vapor Transmission Dynamic Relative Humidity Measurement (23°C 50 %RH) |

ASTM E398 Standard Test Method for Water Vapor Transmission Rate of Sheet Materials Using Dynamic Relative Humidity Measurement | 2.19 Perm (grain/h•ft2•inchHg) at 0.79 mm (30 mil) 125 ng/Pa•s•m2 at 0.79 mm (30 mil) |

| Peel Strength | ASTM C794 Standard Test Method for Adhesion-in-Peel of Elastomeric Joint Sealants | PASS ≥ 5 pli |

Typical VaproBond Applications

|

|

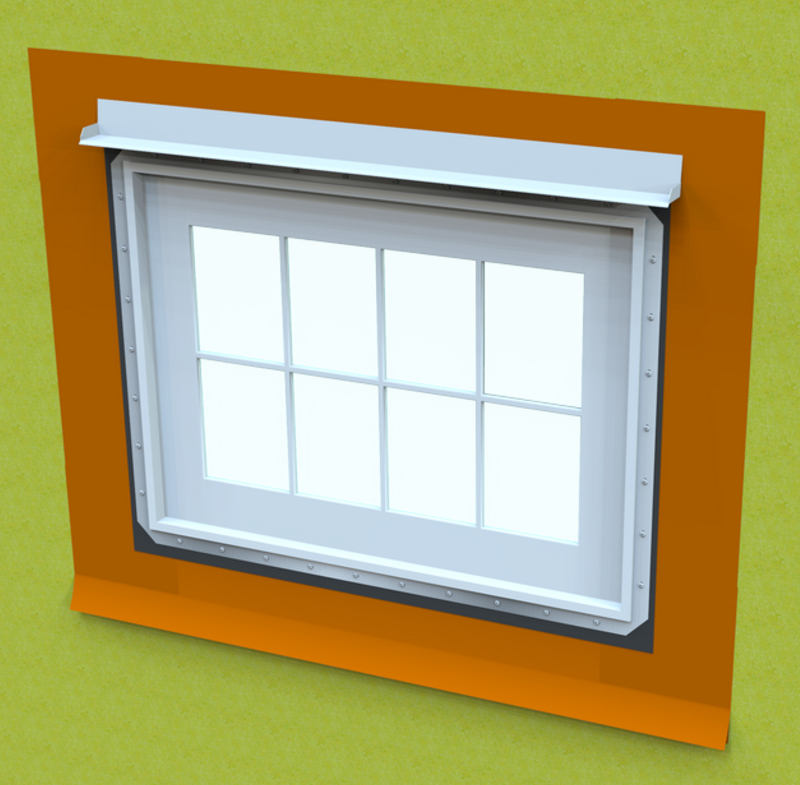

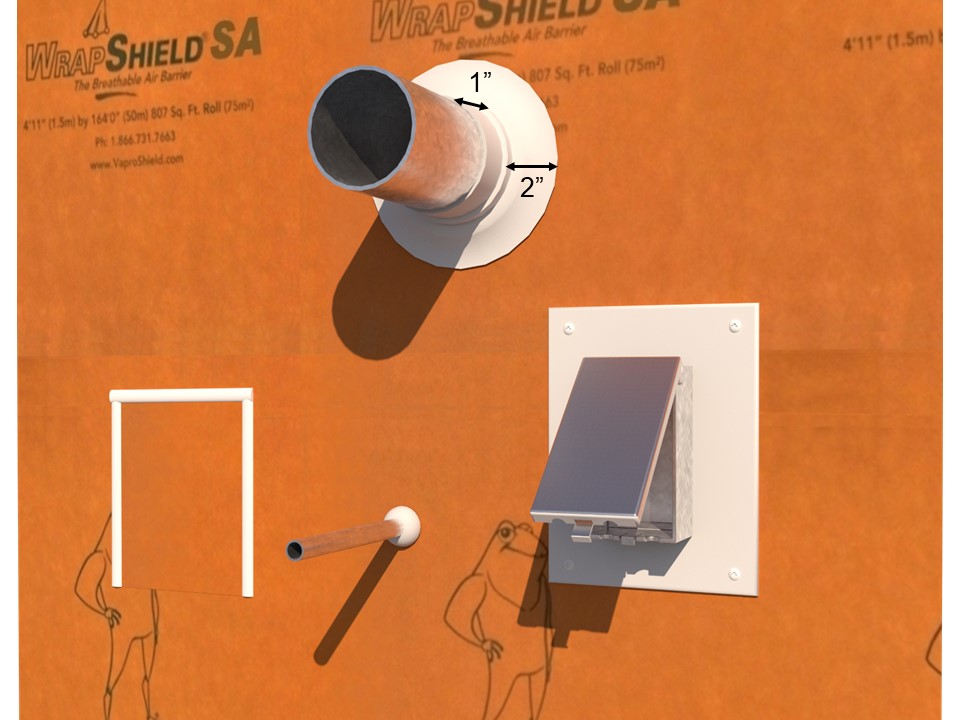

| Commercial Window Apply VaproBond inside the rough opening and 1" (0.25mm) on face. |

Nail Flange Window Apply VaproBond inside the rough opening and 1" (0.25mm) on face. |

|

|

| Wall Penetrations and Patching Apply VaproBond around penetrations and patches. |

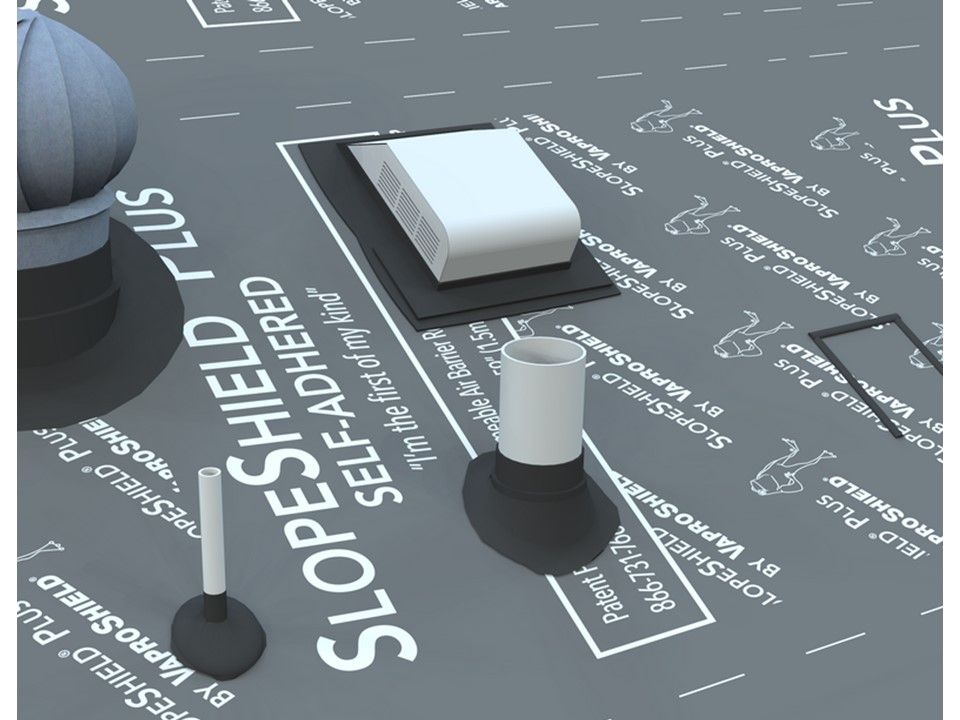

Roof Penetrations and Patching Apply VaproBond around penetrations and patches. |

| Curtain Wall Create a fillet joint by tooling VaproBond (gray) over the top edge of the VaproSilicone Transition strip (white/clear). |