pdf Printer Friendly (481 KB) (PDF)

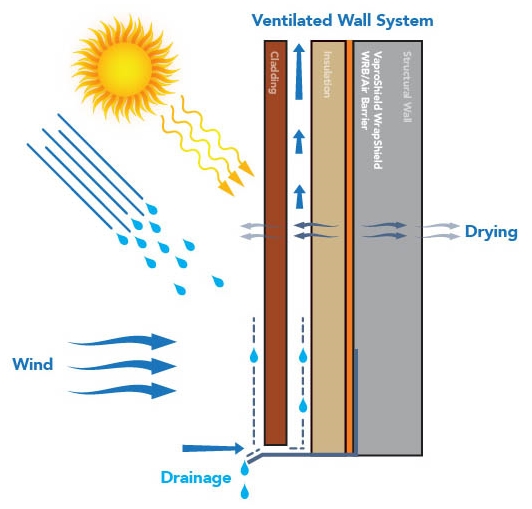

VaproShield’s Installation Best Practices requires a rain screen or ventilated cladding design that ‘vents off’ the resulting vapor pressures when present. This practice prevents reverse vapor drive and allows effective drying in both directions of the wall system.

VaproShield’s Installation Best Practices requires a rain screen or ventilated cladding design that ‘vents off’ the resulting vapor pressures when present. This practice prevents reverse vapor drive and allows effective drying in both directions of the wall system.

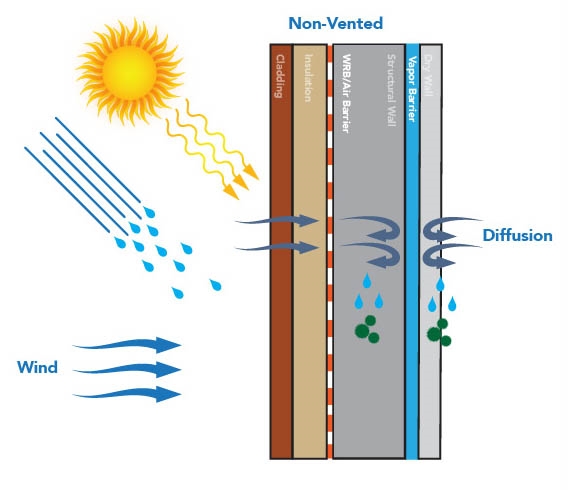

‘Reverse vapor drive’ or ‘inward solar vapor drive’ is used to describe the inward vapor movement due to solar heating of an absorptive cladding such as brick veneer, stucco, and manufactured stone. The highly cementitious material absorbs rain and the hot sun energizes liquid water’s transition into vapor. The released water vapor generates high vapor pressure on the cladding surface. The result is a vapor drive or ‘push’ that can force water vapor into the wall assembly. If water vapor reaches a cooler interior surface that is at or below dew point it results in condensation—a major problem.

Mitigating Vapor Pressure ‘Push’

Vapor pressure’s ‘push’—and subsequent force of water vapor into the wall system—is a complex phenomenon. To effectively mitigate vapor drive several factors should be considered; water vapor transmission rates, hygric-buffering, convection or air movement, and drying capacity from vapor diffusion.

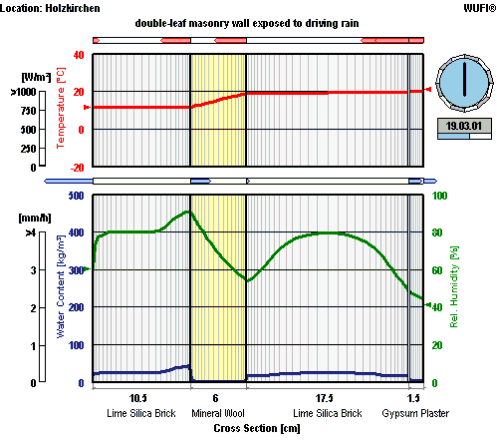

Hygrothermal Modeling Software Pitfalls and Benefits

Hygrothermal modeling is software that evaluates wall sections, analyzing vapor movement that would likely occur during the annual environmental (weather) conditions used for the analysis. Though hygrothermal modeling can appraise the effectiveness of wall designs for various climates, it fails to adequately evaluate the benefits of incorporating drainage and venting into the wall design. In many instances hygrothermal modeling overstates the need for vapor restriction, suggesting a vapor barrier installation to stop the modeled reverse vapor drive.

Preventing Reverse Vapor Drive with Rain Screen Design

Typically, a water resistive barrier/ air barrier is used to control vapor diffusion caused by reverse vapor drive. The amount of vapor restriction or transmittance is calculated using hygrothermal modeling data.A ventilated wall system—sometimes referred as a rain screen—provides a drainage and venting cavity for the wall system. In the open cavity of a rain screen design, convective heat transfer (air movement) occurs when a temperature difference is present. This temperature induced convection (air flow) vents the vapor-laden air out of the wall system, thereby reducing vapor pressures and preventing the reverse vapor drive phenomena that caused the condensation in 1990’s air conditioned homes.

Typically, a water resistive barrier/ air barrier is used to control vapor diffusion caused by reverse vapor drive. The amount of vapor restriction or transmittance is calculated using hygrothermal modeling data.A ventilated wall system—sometimes referred as a rain screen—provides a drainage and venting cavity for the wall system. In the open cavity of a rain screen design, convective heat transfer (air movement) occurs when a temperature difference is present. This temperature induced convection (air flow) vents the vapor-laden air out of the wall system, thereby reducing vapor pressures and preventing the reverse vapor drive phenomena that caused the condensation in 1990’s air conditioned homes.

The rain screen design also offers the incorporation of a highly vapor permeable WRB/Air Barrier system along with the benefit of high drying capacity. In contrast, a vapor barrier material eliminates any drying capacity and can trap moisture.

A common yet problematic solution to prevent reverse vapor drive is the installation of an exterior vapor barrier. Although installing an exterior vapor barrier will prevent the inward vapor drive, it will also stop any outward drying of the wall system through the barrier. It seals out vapor, but seals in any trapped moisture.

A common yet problematic solution to prevent reverse vapor drive is the installation of an exterior vapor barrier. Although installing an exterior vapor barrier will prevent the inward vapor drive, it will also stop any outward drying of the wall system through the barrier. It seals out vapor, but seals in any trapped moisture.

In the 1990’s, air-conditioned homes with unventilated or poorly ventilated brick veneer were showing signs of condensation on the interior vapor barriers during the summer months. In the investigations that followed it was clear that the summer time condensation was in part due to reverse vapor drive.

In the 1990’s, air-conditioned homes with unventilated or poorly ventilated brick veneer were showing signs of condensation on the interior vapor barriers during the summer months. In the investigations that followed it was clear that the summer time condensation was in part due to reverse vapor drive.