Next-Gen Concrete Protection

SlopeShield Plus SA gives contractors the flexibility they need with today's demanding schedules and labor-challenged market.

SlopeShield Plus SA gives contractors the flexibility they need with today's demanding schedules and labor-challenged market.

Benefits:

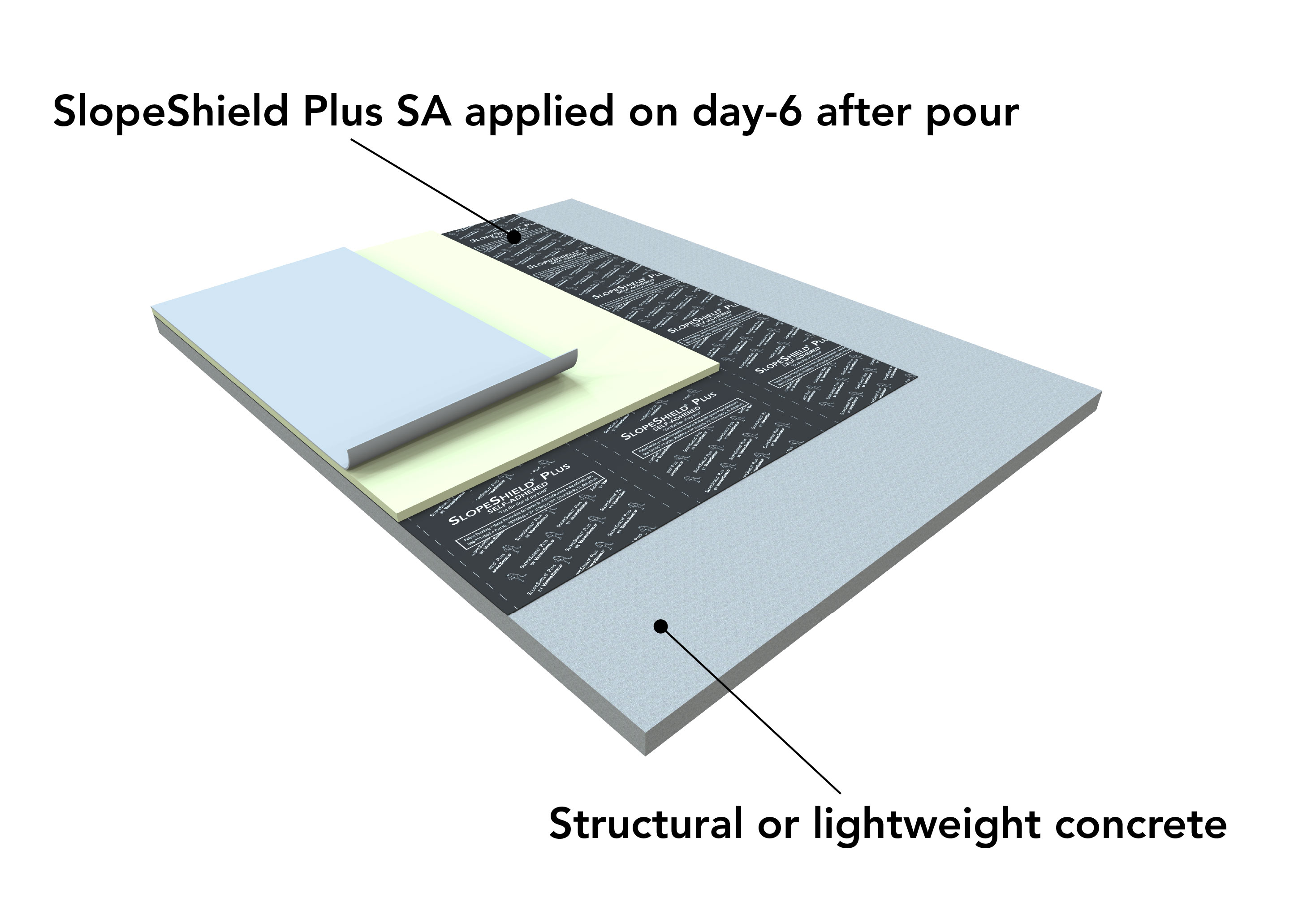

- Apply as early as day-6 after a concrete pour or directly to damp concrete during reroofing

- Prevents weather-related rewetting enabling early dry-in

- Allows interior trades to safely begin BEFORE completing cure cycle

- Eliminates curing calendar resets avoiding costly setbacks

- Streamlines sequencing, protects the structure, keeps project moving

- Saves time, labor, and expensive project setbacks

Green, Fresh Pour Structural Concrete

Install SlopeShield Plus SA over green concrete a minimum of 5 days after pour. Ensure the surface is dry to the touch and meets all the required preparation requirements published in the installation instructions.

| Construct | Pour | Protect Roof Deck |

| Structural concrete roof preparation | Minimum 5-day cure time, apply SlopeShield Plus SA on day 6 or thereafter | Apply SlopeShield Plus SA to partially cured concrete, interior trades can begin |

Lightweight Insulating Concrete

SlopeShield Plus SA can be applied to lightweight insulating concrete. Substrate preparation includes priming the surface with sodium silicate approximately two days after the pour to lock in free lime and stabilize the surface chemistry.

| Construct | Pour/Prepare | Protect Roof Deck |

|

Lightweight concrete roof preparation |

Minimum 5-day cure time, prime within two days, apply SlopeShield Plus SA on day 6 or thereafter |

Apply SlopeShield Plus SA to partially cured concrete, interior trades can begin |

Advantages of SlopeShield Plus SA Over Concrete

|

|

|

Applying SlopeShield Plus SA on day-6 of the cure process:

|

Upon full cure, following American Concrete Institute (ACI) guidelines, SlopeShield Plus SA creates a walkable surface with excellent traction and supports construction equipment |

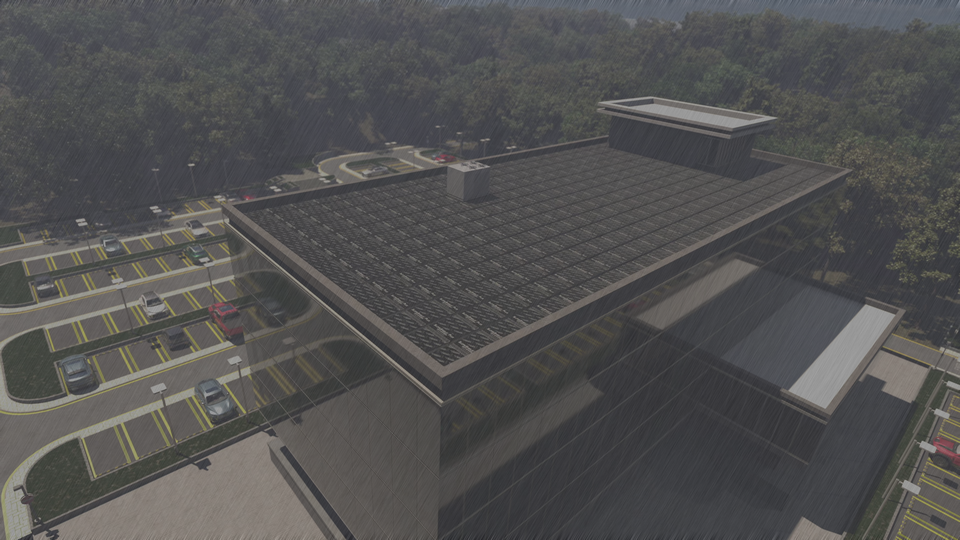

Reroof: Over High Moisture Content Concrete

SlopeShield Plus SA can be applied over existing concrete with high moisture content if the surface is dry to the touch. Applying SlopeShield Plus SA eliminates rewetting—even after rain—reducing schedule uncertainty and maintaining interior operations.

| Remove | Protect | Remain Operational |

|

|

|

|

|

Damp concrete is exposed |

Apply SlopeShield Plus SA to high moisture content concrete |

Concurrent drying and protection maintains project momentum |

Cure Times and Installation Guidance

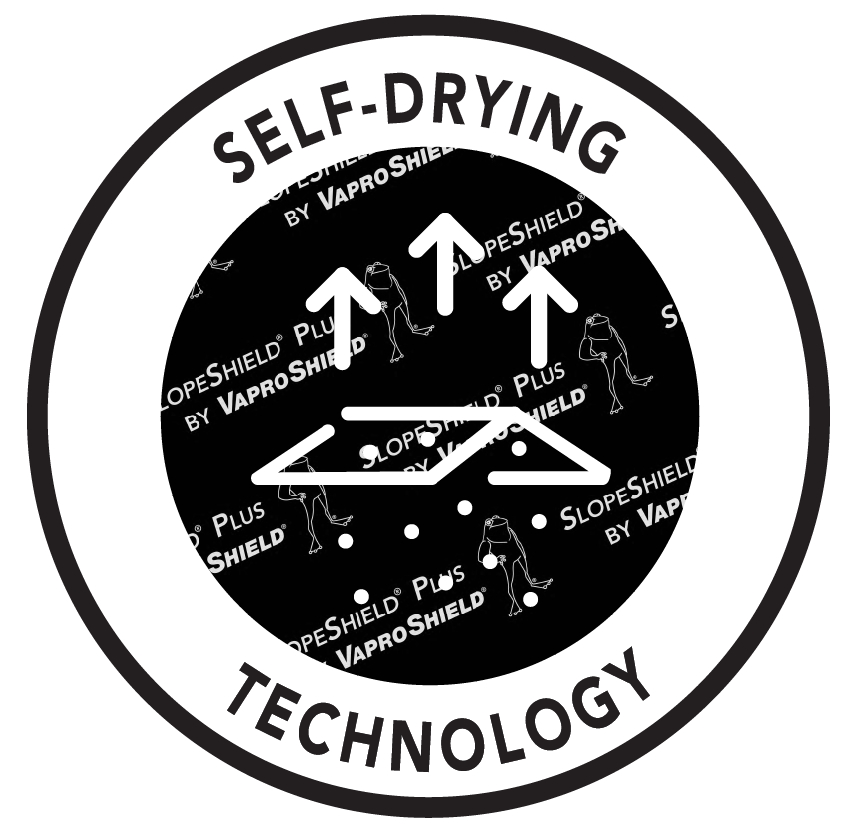

SlopeShield Plus SA does not accelerate the natural curing process of concrete; proper curing is still essential for substrate integrity and performance. While SlopeShield Plus SA protects the concrete from external moisture and allows internal vapor to escape, VaproShield recommends following American Concrete Institute (ACI) guidelines for cure time. This guideline aligns with industry standards to ensure optimal results.

| Continue the Conversation With Us |

|

Concrete Roof Deck Protection Resources

Related Products

August 26, 2024

| Property | Test Method | 2022 Standard (14 Tests) |

| Air Permeance | ASTM E2178 | |

| Apparent Core Density | ASTM D1622 | |

| Compressive Strength | ASTM D1621 | |

| Dimensional Stability at 28 days | ASTM D2126 | |

| Fungi Resistance | ASTM C1338 | |

| Gap Bridging - Declare gap width and temperature tested | ABAA 0004 | |

| Open Cell Content, Volume | ASTM D6226 | |

| Pull Adhesion | ABAA 0002 | |

| Surface Burning Characteristics | ASTM E84 | |

| Tensile Strength | ASTM D1623 | |

| Thermal Resistance for a 25-mm thick specimen | ASTM C518 | |

| Water Absorption by Volume | ASTM D2842 | |

| Water Resistance with a 55-cm head of water | AATCC 127 | |

| Water Vapor Transmission Rate for a 50-mm thick specimen - water and desiccant method | ASTM E96 |

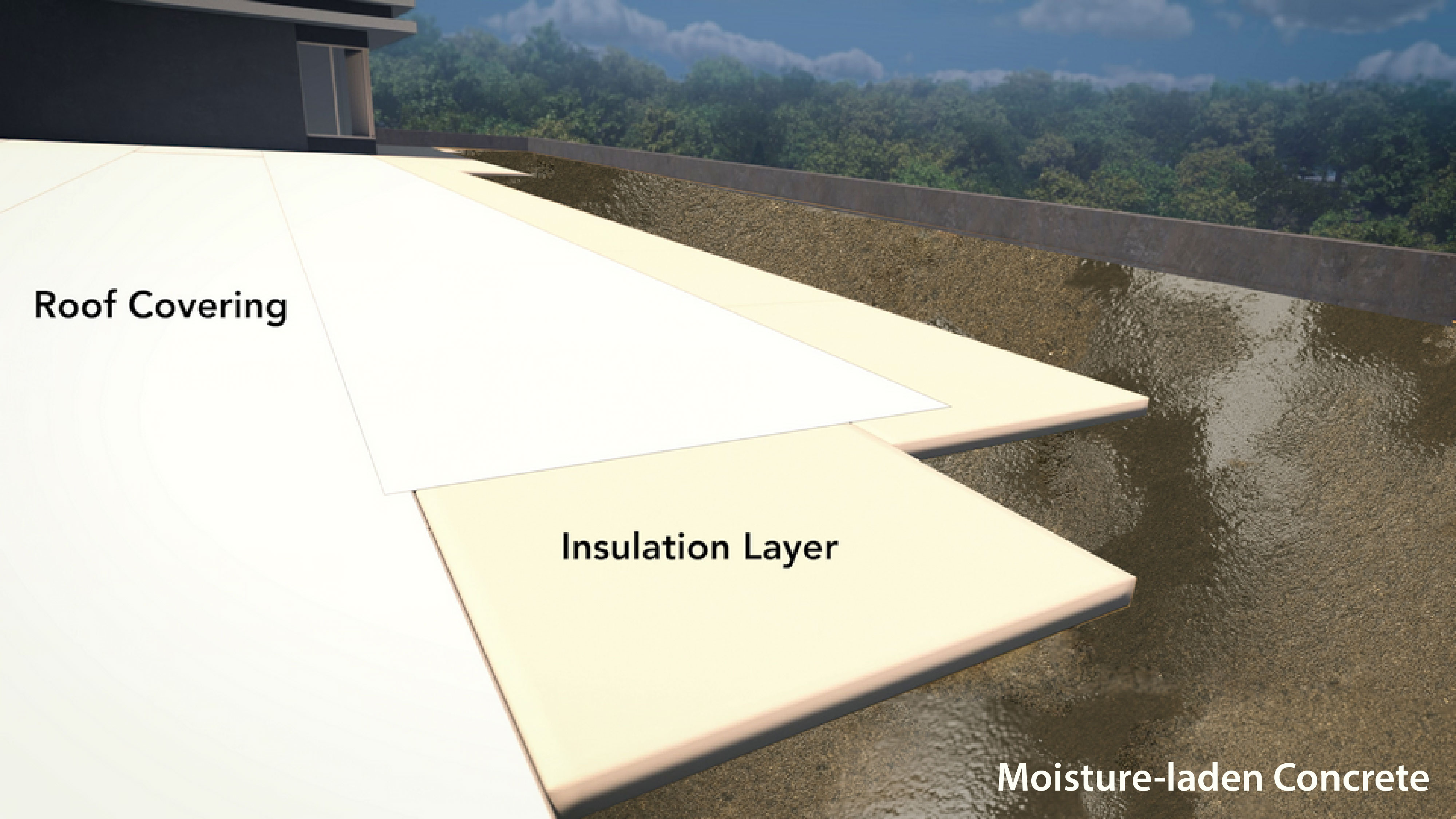

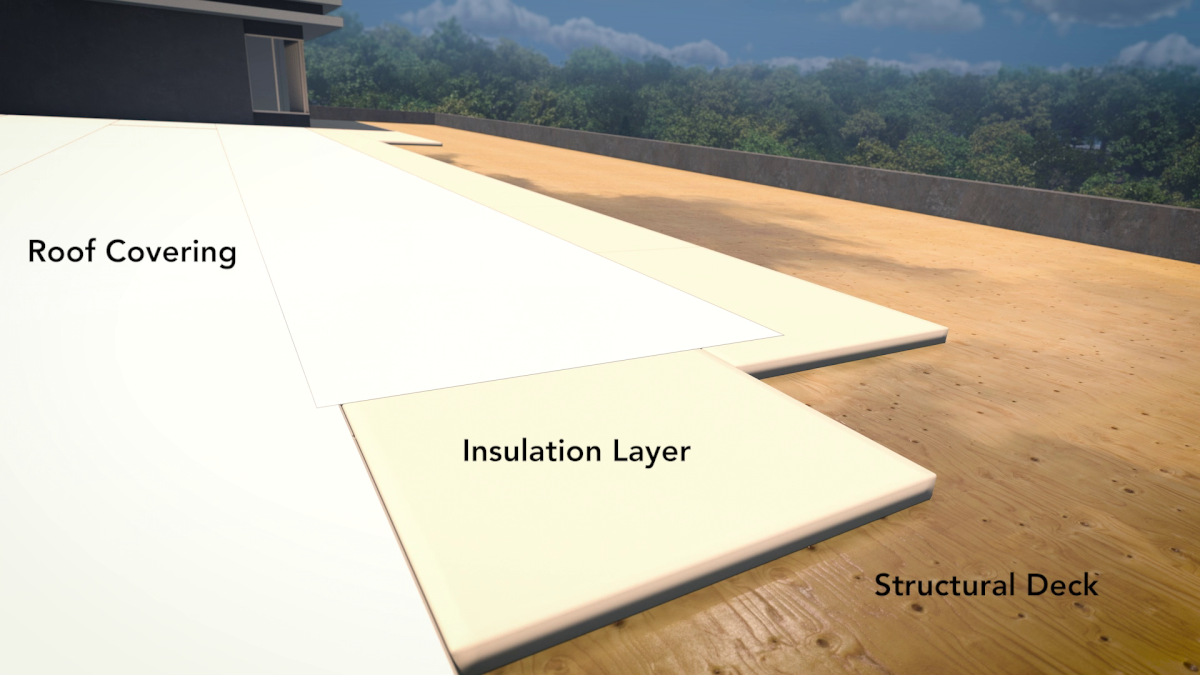

Conventional Reroof Practices

|

|

| A typical low slope roof consists of a roof covering, insulation layer, and structural deck leading to trapped moisture within the roof assembly. | Conventional roofing practices call for the removal of the entire roof assembly which leads to disruptions for occupants and increased overall cost. |

Reduce, Reuse, Renew

Reduce Capital Investment, Reuse Materials, Renew, and be Code Compliant

|

|

|

|

| Tear off aged roof covering. | Install SlopeShield Plus SA allowing damp substrates to dry. | Work continues on reroofing with robust weather protection installed. Building remains occupied. | Install new insulation layer and roof covering. |

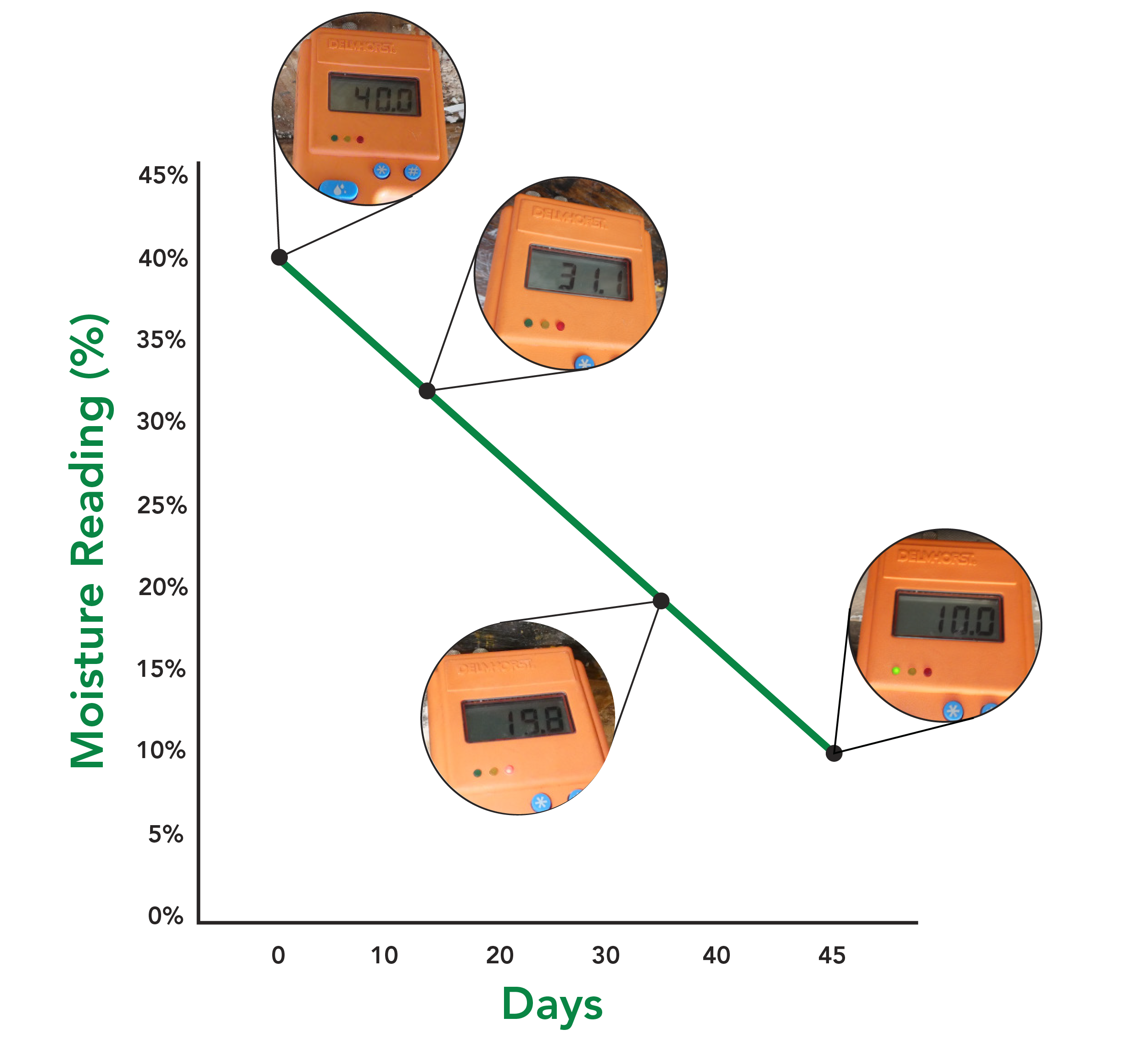

How SlopeShield Plus SA Dries Damp Substrates

Proving Substrate Drying: Case Study

|

SlopeShield Plus SA allowed the double plywood roof deck to dry out over a period of approx. 45 days. The closed cell foam acted as a vapor barrier, negating any downward drying. Only upward moisture movement through SlopeShield Plus SA could take place. |

The Results

Reducing Captial Investment |

Minimizing Occupant Disruption |

|

Challenge: Reroof, reduce labor and capital investment, keep the terminal functional. Solution: SlopeShield Plus SA allowed:

These benefits reduced overall project costs for owners and contractors. |

Challenge: Reroof overburdened vegetative green roof without displacing condo residents on two stories. Solution: SlopeShield Plus SA allowed:

Owners saved valuable HOA monies for additional improvement projects. |

Code Compliance and Energy Efficiency

|

|

|

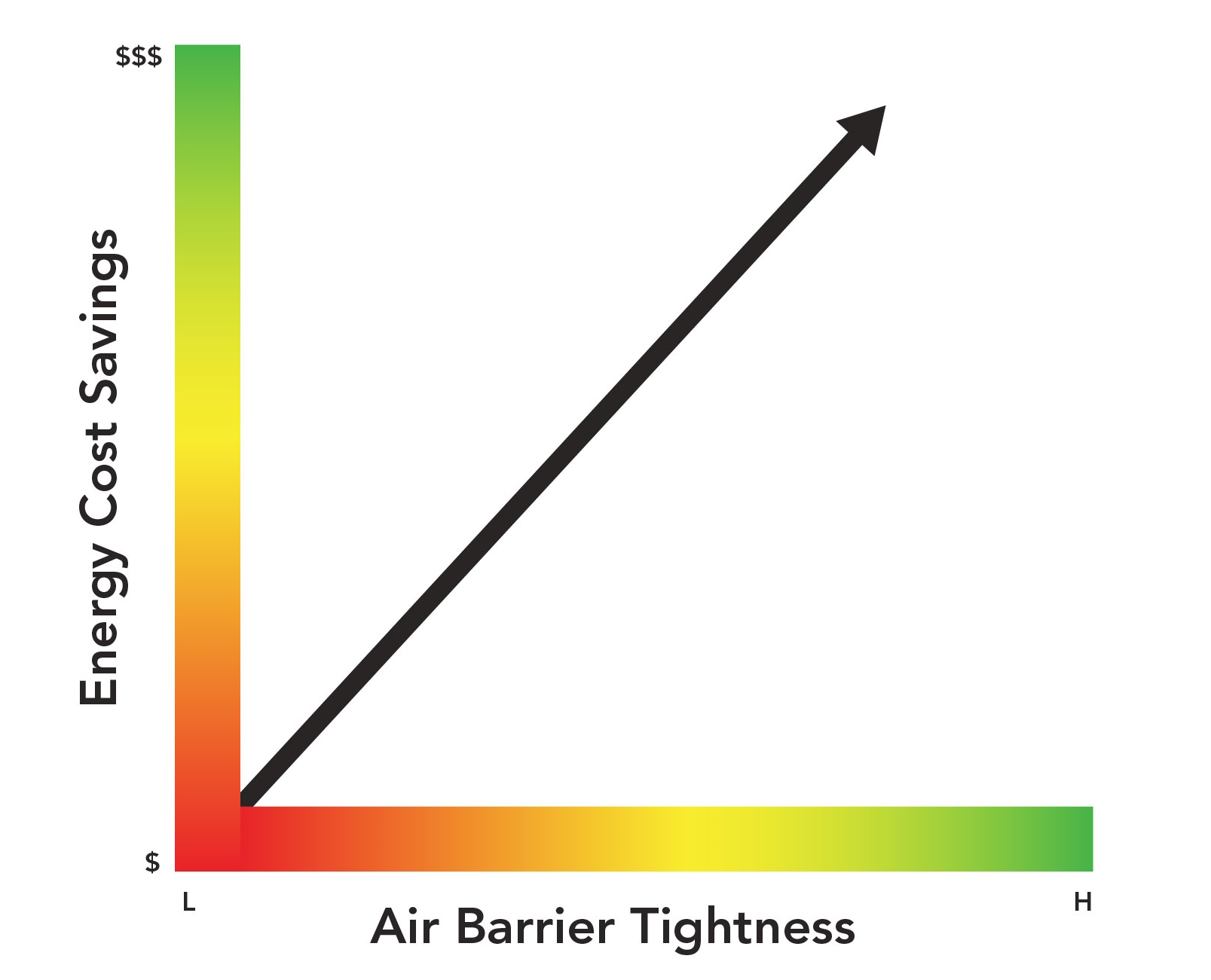

| Meeting/Exceeding Standards: VaproShield products are meticulously engineered to meet and exceed the standards set forth in IECC and IBC. Our high-quality air barrier and permeable vapor retarder membranes safeguard compliance with these codes, guaranteeing the highest quality and adherence to the regulations. | Energy Efficiency: As a code compliant air barrier, SlopeShield Plus SA enhances energy efficiency in the roofing system by minimizing heat transfer and reducing reliance on the HVAC system, significantly contributing to energy savings for the life of the building. | |

Continue the Conversation with Us

We invite you to continue the conversation about self-drying technology with the VaproShield team