Winter 2019 - Special Edition

Winter 2019 - Special Edition

Highlights:

NEW SlopeShield Plus Self-Adhered

- Advanced Patent-Pending Technology

- SlopeShield Plus Difference

- Roofing System Compatibility

- Complete Roof and Wall, Water-Resistant, Vapor-Permeable, Air Barrier System Accessories

Winter 2019

Highlights:

- Technical Bulletin: Adhesive Performance

- Advancements in Adhesive Technology

- 2018 ENR Award Winner

- Superior Customer Support: A Case Study

- Climate Control: Installed in Variable Weather

- VaproLiqui-Flash Available in a Pail

- Submittal Tools

Fall 2018

Highlights:

pdf Technical Bulletin: Adhesive Performance (568 KB)

- Advancements in Adhesive Technology

- Innovation and Testing

- Why Eliminate Primers?

- Faster and More Efficient: VaproShield Membranes

- Lab and Field Testing

June 2018

Highlights:

- What Happened to pdf Moisture Management (5.90 MB)

- Two-component Window Flashing

- VaproShield on the Move

- Ribbit Resource: Reexamining Current Practices

January 2018

Highlights:

- ‘Tame the Rain’ article authored by Kevin Nolan

- VaproShield receives Elevation Award

- Technical education – What is Reverse Vapor Drive

- Continued NFPA 285 compliance

- VaproShield publishes interactive Project Portfolio

- VaproShield launches one-click submittal packages

Fall 2017

Highlights:

- VaproShield Receives Elevation Award

- New Product: VaproSilicone Transition Materials

- Fastener Penetration Tech Bulletin

- VaproShield on the Move

Summer 2017

Highlights:

- What is Reverse Vapor Drive?

- Project Highlights

- VaproShield on the Move

pdf

(5.85 MB)

Summer 2017

Highlights:

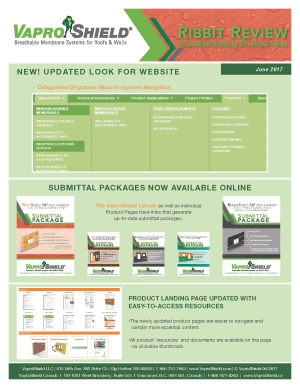

- Website Menu Updates

- Submittal Packages

- Product Page Updates

pdf

(9.06 MB)

Winter 2017

Winter 2017

Highlights:

- VaproShield wins prestigious award

- NEW! Product: VaproShim SA Self-Adhered

- Upcoming Trade Shows

- Industry News

Fall 2016

Fall 2016

Highlights:

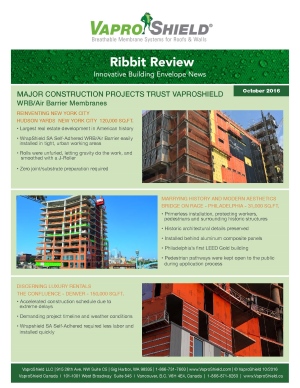

- Reinventing New York City: Hudson Yards - New York City - 120,000 sq.ft.

- Marrying History and Modern Aesthetics: Bridge on Race - Philadelphia - 31,000 sq.ft.

- Discerning Luxury Rentals: The Confluence - Denver - 150,000 sq.ft.

- Lincoln Park Redevelopment: Webster Square - Chicago - 60,000 sq.ft.

Summer 2016

Highlights:

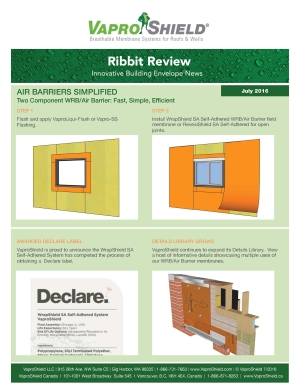

- Air Barriers Simplified: Two Component WRB/Air Barrier: Fast, Simple, Efficient

-

VaproShield Awarded Declare Label

- VaproNews: Twelve Stories in NINE Days!, VaproShield Membranes Ideally Suited for Modular

- Ribbit Resource: Top Builder to Pay for Condo Defects

Spring 2016 - Special Edition

Highlights:

- WrapShield SA Self-Adhered system obtains Declare Label

Spring 2016

Highlights:

- New VaproSystem Accessories: VaproShim and VaproMat

- Projects installed in various weather conditions

- VaproShield on the Move: Upcoming Tradeshows

Ribbit Resource:

- “Insight Flow-Through Assemblies"

Fall 2015

Highlights:

- VaproAirBarrier System

- Key Air Barrier Questions and Answers

- WrapShield SA Outperforms Competitors

Ribbit Resource:

- NFPA 285 Substitutions are Acceptable

- All VaproShield Membranes are non-asphaltic and have a Class A Fire Rating

Summer 2015

Highlights:

- WrapShield RS Rain Screen Launched

- WRB/AB with built-in rain screen drainage matrix and integrated tape

- No messy, sticky, weather sensitive primers required

- Phase construction friendly install in temperatures as low as 20˚F

- No change to design or installation required

Spring 2015

Highlights:

- VaproShield Membranes Approved by ABAA

- WrapShield SA Self-Adhered and RevealShield SA Self-Adhered approved

- Category had to be created to accommodate VaproShield's innovative products

Ribbit Resource:

- In Case You Missed It

- Highlights of our most popular Ribbit Resource Articles

Fall 2014

Highlights:

- Building Envelope Solutions for Prefab/Modular Construction

- VaproShield: Chosen for Modular Post-Disaster Housing Units

- VaproShield Participates in First Prefab Micro Housing Project

- Stacking Up

- Hill 7 – Field and Off Site Prefab

Ribbit Resource:

- Pitfalls of Tape Applied After the WRB is Installed

- Horizontal taped seams create reverse lap, allowing moisture intrusion.

- Tape installed in dirty or wrinkled membranes does not adhere.

- Tape installed carelessly over fasteners prevents a full seal.

But, VaproShield membrane systems solve these issues.

Summer 2014

Summer 2014

Highlights:

- RevealShield SA Self-Adhered Launched

- Only a single layer is required behind open joint cladding

- No messy, sticky, weather sensitive primers required

- Phase construction friendly install in temperatures as low as 20˚F

Spring 2014

Spring 2014

Highlights:

- VaproShield: Proven Performance, Proven Green

- VaproShield products used in Living Building Challenge for renewable design

- VaproShield membranes contribute to LEED Platinum status for The National Renewable Energy Lab

- WrapShield used in Net Zero Energy home

- VaproShield Membrane Defeats Construction Delays

Ribbit Resource:

- VaproShield Performs to the "World's Most Rigorous Green Building Performance Standard"

- VaproShield membranes are free of all Red List chemicals.

- Features 7 key performance areas, or "Petals". Criteria are: Site, Water, Energy, Health, Materials, Equity, and Beauty, which determine overall sustainability

Winter 2014

Winter 2014

Highlights:

- VaproShield Membranes Perform In Extreme Weather

- WrapShield SA withstands Minnesota's coldest December in 41 years

- Norton Sound Hospital in Nome, Alaska installed WrapShield SA in 0˚F temperatures

- Waterfront Station in Yukon Territory, Canada uses VaproShield in volatile climate

- WrapShield SA withstands Hurricane Sandy without any signs of damage

Ribbit Resource:

- Impermeable Self-Adhered Flashing Prevents Outward Drying – Excerpts from blog entry via Built Environments

- Blog entry features images displaying moisture penetration problems and diagrams explaining moisture and vapor movement between exterior, cladding, sheathing, and wall cavity.

Summer 2013

Summer 2013

Highlights:

- Major Construction Projects Trust VaproShield Membranes

- $415 million Music City Center in Nashville, TN trusts VaproShield to protect their investment

- WrapShield SA used on 56 steel and concrete prefabricated modules in the unique, seven-story, 28 unit apartment building known as "The Stack".

Ribbit Resource:

- What is NFPA 285?

- NFPA 285 evaluates the vertical and horizontal spread of fire away from the point of origin. During the 30-minute test, temperatures are monitored throughout the wall using dozens of thermocouples embedded in the insulated wall panel. Exterior face, core, air cavity, and interior temperatures at various levels throughout the wall assembly are recorded.

Fall 2012

Fall 2012

Highlights:

- VaproShield Launches RevealShield for Open Joint Cladding Systems

- Single Layer = Less Material Costs and Installation Time

- Reduce Contractor Liability

- Install Year Round

- Reduce Installation Time by using all VaproShield components

- VaproBatten, RevealFlashing, and VaproLiqui-Flash work in unison saving valuable installation time, reducing contractor liability, and offering more design opportunities

Ribbit Resource:

- Water Intrusion Problems – Excerpts from "Rainscreen Description Manual" by Building Envelope Engineering (BEE)

- Window and flashing details vital, as these are the most common areas for leaks

- Many residential and commercial buildings suffer water intrusion problems, hidden by cladding

- Rain Screen Design can be used for new construction projects or retrofit to mitigate liability

Summer 2012

Summer 2012

Highlights:

- VaproShield Launches WrapShield with Integrated Tape

- Easier to seal horizontal seams and create necessary shingle effect

- Minimizes labor for installation

- Allows vapor moisture to escape

- Tape can with stand extreme temperatures

- VaproLiqui-Flash launched

- Bonds without primers to VaproShield membranes and most common wall substrates

- Creates monolithic, waterproof surface while remaining permeable to water vapor.

Ribbit Resource:

- ASTM E2357

- ASTM E2357 Standard Test Method for Determining Air Leakage of Air Barrier Assemblies measures performance of an assembled system, rather than the amount of air leakage through a single component

- Rigorous test that includes extreme wind gust load conditions

Winter 2012

Winter 2012

Highlights:

- Profiles of Major Projects

- Music City Center uses over 400,000 Sq.Ft. of WrapShield SA on $415 million project

- Radisson BLU hotel uses 92,000 Sq.Ft. of WrapShield SA in harsh Minnesota winter weather.

- SlopeShield used in restoration of 77 year old Peabody Opera House

Ribbit Resource:

- Four Ways Water Moves In/Out of Buildings

- Bulk Water (i.e. rain, runoff) is driven by gravity, wind, and pressure differences. It is managed by moving water down, off, and away from the building.

- Capillary water moves under tension through porous building materials or through narrow channels between building materials, which act like straws. The primary defenses are capillary breaks in appropriate locations.

- Air-transported moisture is carried into or out of buildings by air leaks. Air moves through holes in the building envelope, propelled by pressure differences. Air-transported moisture is managed by preventing air leakage with a continuous air barrier.

- Vapor diffusion is the movement of water as a gas through material according to differences in relative humidity or vapor pressure.

Summer 2011

Summer 2011

Highlights:

- VaproShield Launches SlopeShield SA Water-Resistive, Vapor Permeable Roof Underlayment

- Zero VOC's

- High Vapor Permeance

- Water Resistive

- Low Temperature Application

- No Primer Required

- No Tapes or Mechanical Fasteners

Ribbit Resource:

- Air Barriers Reduce Energy Costs

- A study conducted by National Institute of Standards and Technology and backed by the US Dept. of Commerce, on the financial impact of air leakage and the operation of the building's mechanical systems concluded air barriers save money and reduce energy consumption by as much as 40% per year over the life of the building.

Winter 2011

Winter 2011

Highlights:

- VaproShield Launches VaproCaps

- Preformed head caps with a center throat hole, sealing the membrane at fastener penetration.

- Designed and tested to withstand wind loads and protect against water intrusion at screw penetraions

Ribbit Resource:

- Managing the Stack Effect

- Stack Effect is caused by rising warm moist air, contributes to air infiltration or air leakage through holes at the base of buildings and air exfiltration at the top of the building

- Studies have shown moisture laden air is the primary cause of condensation forming within building assemblies

Fall 2010

Fall 2010

Highlights:

- VaproShield Launches WrapShield SA Self-Adhered

- No Primer Required

- Contributes to LEED certification

- Passed Air Barrier ASTM E 2357.05 as per Air Barrier Association of America

- 20 year Warranty

- 6 months UV and Climate Exposure

Ribbit Resource:

- Why Should I Care About Perms and Permeability?

- Proper building envelope design promotes continual drying by allowing vapor to escape

- Membranes with high perm value reduce risk of condensation, promote escape of moisture, and help building "dry-out" during the construction phase.