pdf Printer Friendly (PDF) (2.20 MB)

| Fastener Penetrations Through VaproShield WRB/Air Barriers |

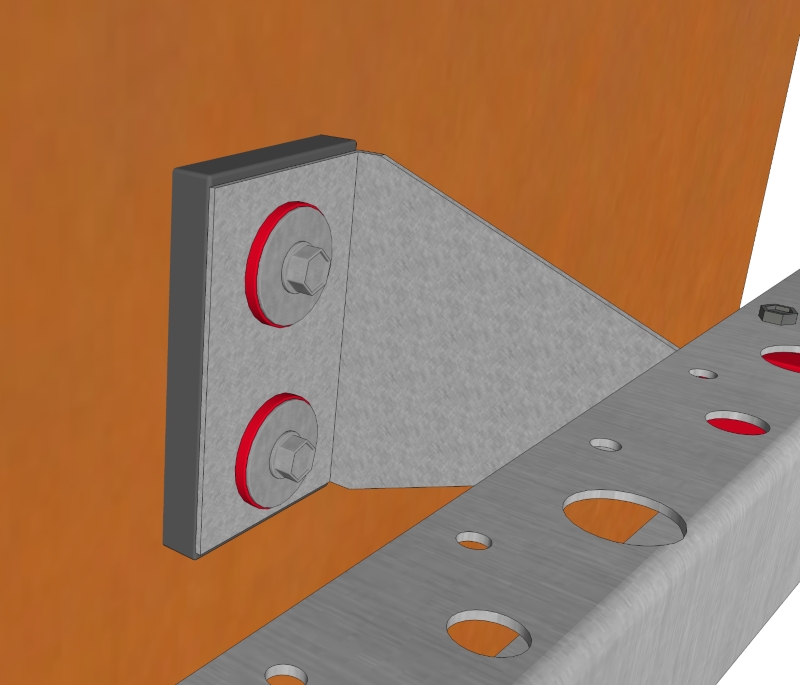

Figure 1 shows cladding attachment system fasteners penetrating WRB/Air Barrier

Figure 1 shows cladding attachment system fasteners penetrating WRB/Air Barrier

Overview

Fasteners (screws, nails, etc.) used with cladding attachment systems will need to penetrate the WRB/Air Barrier (Figure 1). However, the WRB/Air Barrier must still provide air and water tight performance.

If You Don’t Test – You Are Just Guessing

VaproShield Membrane Fastener Penetration Water Testing – ASTM E331

VaproShield’s approach to measuring air and water tightness around fastener penetrations uses the ASTM E331 Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference.

By using ASTM E331 (not ASTM D1970/ D7349) as a standard water test method, VaproShield ensures penetrations used in cladding assembly attachments will hold out water even under extreme rain events.

|

VaproShield does not promote the terms ‘self-sealing’ or ‘self-healing,’ as both terms can be misleading. As an industry leader in fail safe building envelope solutions, VaproShield conducts testing on fastener penetrations and attachment systems of all types. Our tests accurately simulate field installation. |

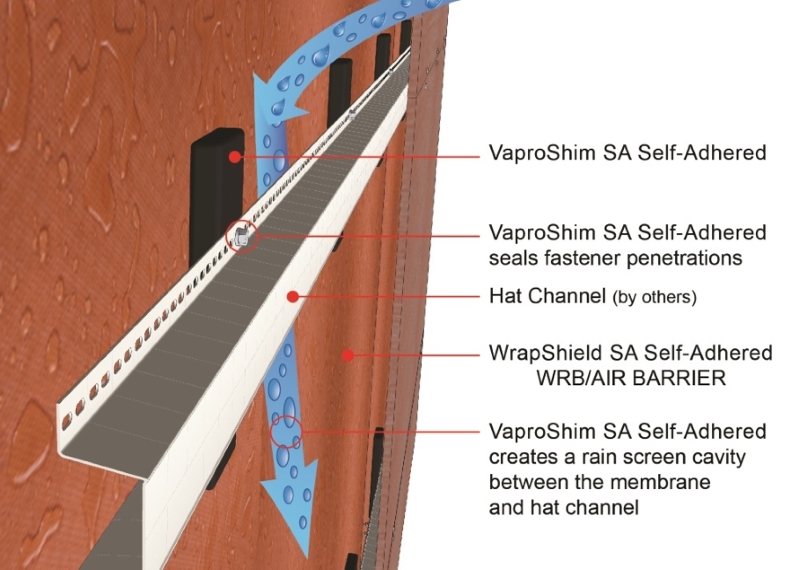

ASTM E331 Testing Mock-up, cladding attachments are fastened through membrane, and placed in test chamber for water and air holdout

ASTM E331 Testing Mock-up, cladding attachments are fastened through membrane, and placed in test chamber for water and air holdout

Testing Methodology: ASTM E331

1. A WRB/AB membrane is placed over a mockup test frame according to the specified project detail—including framing, steel gauge, sheathing, and fastener specifications.

2. Cladding attachments are fastened through the membrane.

3. The water test is performed.

| Conclusion This testing methodology provides assurance that fastener penetrations through VaproShield WRB/ AB systems will hold out water under real world and extreme environmental conditions. |

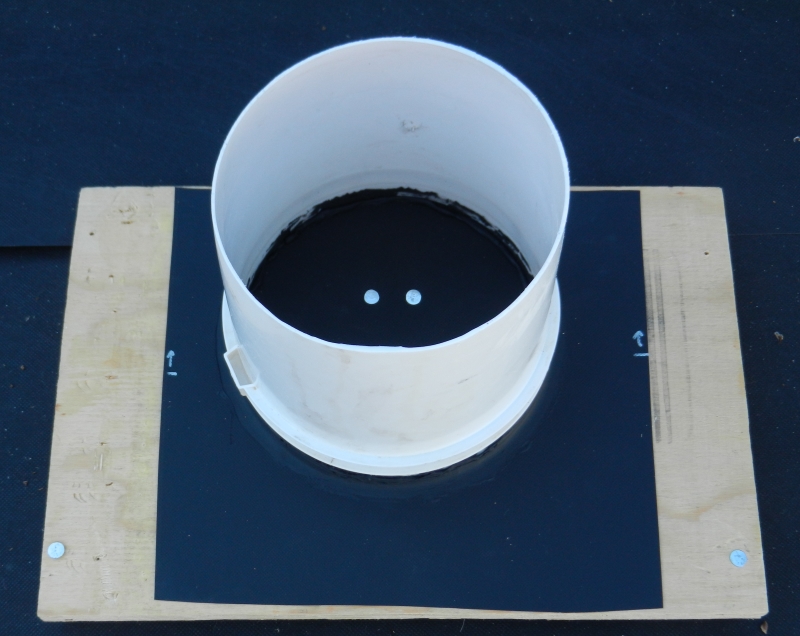

Image depicts the AATCC 127 Hydrostatic Pressure testing apparatus, which uses a 550 mm (22 inch) head of water to evaluate the water holdout of waterproofing materials.

Image depicts the AATCC 127 Hydrostatic Pressure testing apparatus, which uses a 550 mm (22 inch) head of water to evaluate the water holdout of waterproofing materials.

Water Holdout Test - AATCC 127

To pass this test, the underside of the membrane must show less than 3 drops of water following five (5) hours of 550mm head pressure exposure. The modified AATCC 127 Hydrostatic Pressure Test is routinely and successfully performed on all VaproShield’s WRB/AB membranes and fluid-applied flashing materials; VaproLiqui-Flash and VaproBond.

Fastener Penetration Best Practices

VaproShield’s WRB/AB membranes and systems demonstrate excellent water holdout when manufacturer instructions and installation best practices are followed.

The following measures can provide additional confidence for a water tight system:

- Ensure fasteners are secured through a stud or stable substrate, fastened snug and tight with the membrane.

- Use gasketed fasteners at the fastener head for additional water holdout.

- If a fastener fails to secure and needs to be removed, seal the penetration with VaproBond sealant or VaproLiqui-Flash.

- In the event of a damaged membrane (rip, tear, etc.,) refer to VaproShield’s published details on penetrations and repair.

- Use VaproShim SA™ Self-Adhered Neoprene accessory if a fastener bracket fails to provide a snug fit against the membrane. VaproShim SA™ Self-Adhered seals fastener penetrations and creates the desired vertical rain screen drainage when installed under horizontal or vertical cladding attachment components.

| Misuse of ASTM D1970 |

ASTM D1970 Defined

ASTM D1970 is the Standard Specification for Self-Adhering Polymer Modified Bituminous Sheet Materials Used as Steep Slope Roofing Underlayment for Ice Dam Protection. This standard, like many ASTM Standards, is comprised of numerous tests designed for evaluating the performance of a building material; in this case, asphalt/bituminous self-adhering roof underlayment.

Misuse of ASTM D1970

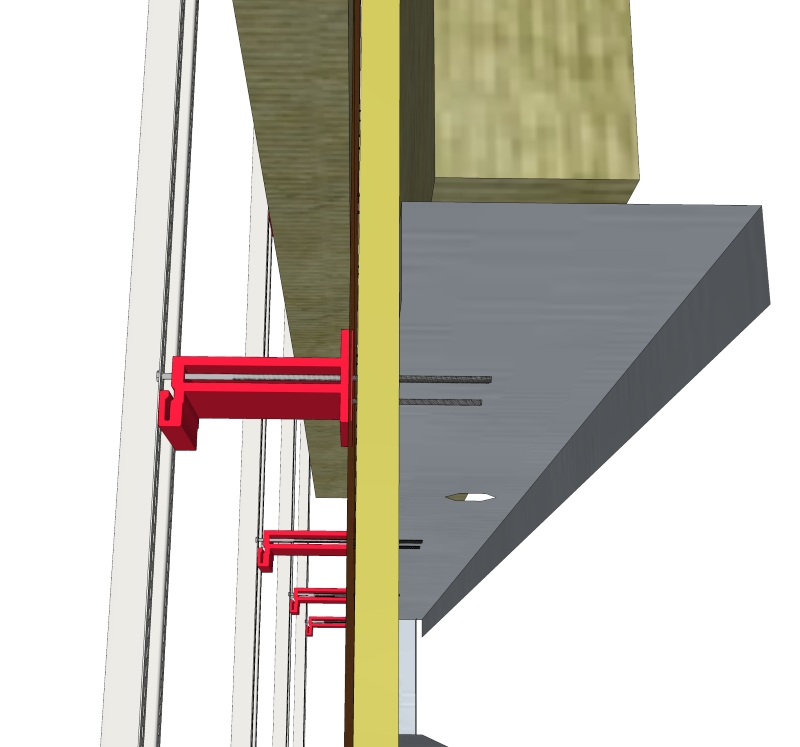

Figure 2. ASTM D7349 is specifically designed for roofing nails installed into a plywood substrate.

Figure 2. ASTM D7349 is specifically designed for roofing nails installed into a plywood substrate.

Some manufacturers cite their ASTM D1970 results as evidence of being a ‘self-sealing material’ for all fastener types. This can be misleading, as ASTM D1970 is a standard specification and not a test.

ASTM D1970 and Related Tests

Included amongst the multiple tests required within ASTM D1970 is the ASTM D7349-Standard Test Method for Determining the Capability of Roofing and Waterproofing Materials to Seal Around Fasteners. ASTM D7349 is specifically designed for roofing nails installed into a plywood substrate (Figure 2). This test is very appropriate for a steep slope roofing underlayments, and one that VaproShield materials pass as well.

| Misuse of ASTM D7349 |

Figure 3 illustrates self-drilling screws penetrating the metal structural framing Incorrectly referred to as a self-sealing test, the ASTM D7349 is technically a ‘nail sealability test’. The problem with using this test to measure sealability is that most cladding attachment systems used in commercial construction are comprised of brackets, clips, extrusions, and screws that will penetrate the WRB/AB membrane. These screws can be up to ¼” diameter and use self-drilling tips to pierce the metal structural framing (Figure 3).

Figure 3 illustrates self-drilling screws penetrating the metal structural framing Incorrectly referred to as a self-sealing test, the ASTM D7349 is technically a ‘nail sealability test’. The problem with using this test to measure sealability is that most cladding attachment systems used in commercial construction are comprised of brackets, clips, extrusions, and screws that will penetrate the WRB/AB membrane. These screws can be up to ¼” diameter and use self-drilling tips to pierce the metal structural framing (Figure 3).

| Conclusion To claim that a material is self-sealing under these conditions by citing a test that uses roofing nails is misleading and problematic. |

Furthermore, commonly-used gypsum wall sheathing performs vastly different than plywood when penetrated with large self-tapping screws at speeds approaching 6000 rpms. In a rain screen application on any given moderate high-rise, there are thousands of such cladding penetrations— all subject to varying levels of wind driven rain and air flows.

Note: Always consult the Engineer and Water Proofing consultant of record before changing original project designs.

Review information on our membranes, sealants and installation guidelines, if you have further questions about sealability Contact us, or call our Tech Team at (866) 731-7663 opt. 5.